Home LED Light Products ASA PMMA Coated Plastic PVC Corrugated/Trapezoid/Wave/Transparent/Translucent/Rroof Tile/Sheet Extrusion Production Extruding Making Extruder Machine

ASA PMMA Coated Plastic PVC Corrugated/Trapezoid/Wave/Transparent/Translucent/Rroof Tile/Sheet Extrusion Production Extruding Making Extruder Machine

| Price: | US $ 65000-90000/Set |

|---|---|

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,D/P,Western Union |

| Prod Model: | ACE65/132-80/156 |

|---|---|

| Cavity: | Single Cavity |

| Extruder Gearbox: | High Torque Vertical Type |

| Gearbox Bearing: | NSK,SKF |

| Motor Brand: | Weg,Siemens |

| Extruder Model: | Ace65/132-80/156 |

| Extrusin Speed: | 1.0-2.0m/Min |

| Barrel & Screw: | Bimetallic Barrel & Screw |

| Controller: | Siemens PLC |

Product Description

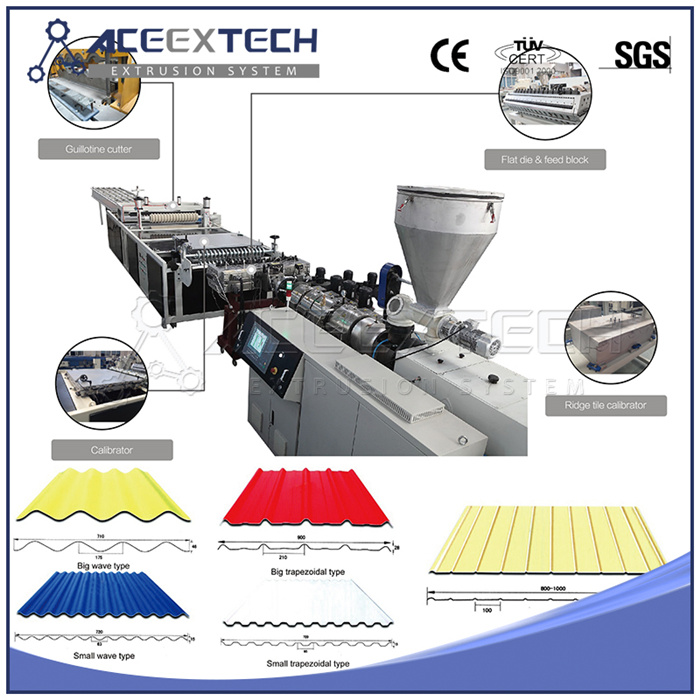

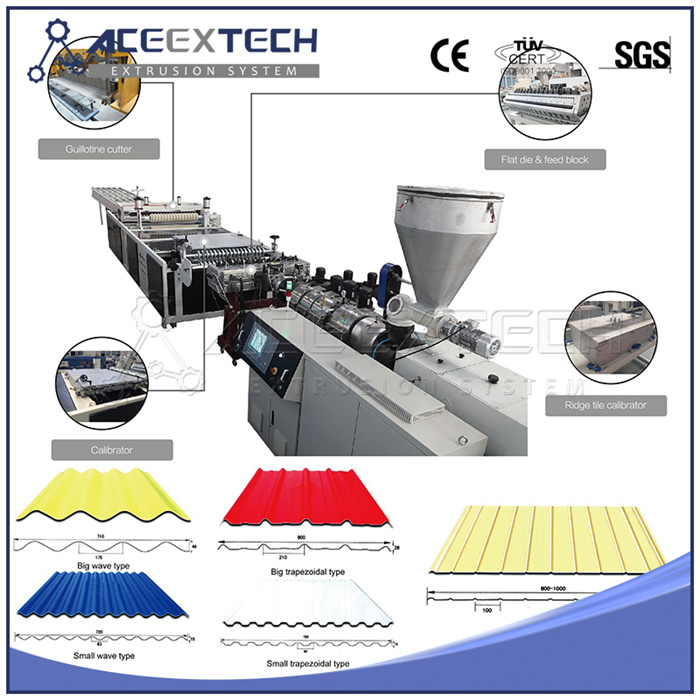

ASA PMMA Coated plastic PVC Corrugated/Trapezoid/Wave/Transparent/Translucent/Rroof Tile/Sheet Extrusion Production Extruding Making Extruder machine

ASA PMMA Coated plastic PVC Corrugated/Trapezoid/Wave/Transparent/Translucent/Rroof Tile/Sheet Extrusion Production Extruding Making Extruder machine for production of customizes different solutions according to clients' demands on product structure, shape which has width from 720mm to 1130mm and thickness from 0.8

mm to 3.0mm with round wave type and trapezoidal shape, also possible for multi-layers design, and turn-key solution is pleased to be provided;

ASA PMMA Coated plastic PVC Corrugated/Trapezoid/Wave/Transparent/Translucent/Rroof Tile/Sheet Extrusion Production Extruding Making Extruder machine for production of customizes different solutions according to clients' demands on product structure, shape which has width from 720mm to 1130mm and thickness from 0.8

mm to 3.0mm with round wave type and trapezoidal shape, also possible for multi-layers design, and turn-key solution is pleased to be provided;

special designed screw has excellent shearing and plasticizing esoft and rigid PVC profile co-extrusion lineffect, to ensure the quality of the products; high speed cooling of extrusion and calibration mold makes the production lineal speed faster and more efficient.

The unit consists of Conical (Parallel) double screw extruder-Co extruder-Flat die and feed block-calibration table include calibrator, haul off and cutting sytem-Stacker-ridge tile calibrator

Advantages:

♦ Specified screw design for better material plasticizing &mixing effect, For high filling formula, bimetallic screw and barrel can guarantee perfect solution;

♦ Co-extruder equipped with dehumidifying and drying system can be applied to produce PMMA/ASA composite material, which ensures the good performance and high quality of final product;

♦ T-die adopted hanger style can be applied to produce single PVC melt material or multi-layer compound material, and flow surface adopts polish and electroplated treatment;

♦ Specified design of Calibrator ensuring faster heating transfer and quickly cooling calibration;

♦ Guillotine cutter ensuing flat and chip free cutting, and tracking cutter especially for thick and high filler product;

♦ Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently.

Work flow and detailed information:

| Feeder | • To feed material into extruder; |

| Extruder | • World famous brand electrical component such as Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Co-extruder | • World famous brand electrical component such as Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Intelligent PLC controlling system with human-friendly interface. |

| Flat die and feed block | • Coat hanger type • 5CrNiMo steel and P20 material • Apply to single lay and muti layer with top layer adopts PMMA/ASA co-extrusion • Support trolley is include |

| Calibration table | •Specified design of Calibrator ensuring faster heating transfer and quickly cooling calibration •Guillotine cutter ensuing flat and chip free cutting •Tracking cutter especially for thick and high filler product • Haul off machine with adopts wear-resisting rubber roller • Speed driving by frequency inverter |

| Ridge tile calibrator | • Pneumatic driving • High quality cast aluminum material • Double station heating oven is include |

| Stacker | • Stainless steel304 as touching material |

Main elements brand:

♦ Motor: Siemens, WEG, SEW

♦ Gear reducer: SEW, FALK

♦ Bearing: SKF, FAG, NSK

♦ Air cylinder: Festo, SMC, AirTac

♦ PLC interface and module: Siemens, Schneider, Beckhoff

♦ Frequency inverter: ABB, Schneider, Siemens

♦ Servo motor: Lenze, Delta

♦ Pressure sensor: Dynisco, Gefran

♦ Low voltage component: Siemens, Schneider, Omron, LS

♦ Temperature controller: Omron, RKC

♦ Solid state relay: Crydom, Celduc

Technical Parameter:

| Structure | Material | Width | Thickness | Extruder Model | Designed Output |

| Single layer | PVC | 720-1130mm | 1.0-3.0mm | ACE80/156 | 350-400kg/h |

| Double layers | ASA/PMMA+PVC | 720-1130mm | 1.0-3.0mm | ASS50/30+ACE80/156 | 350-400kg/h |

| Triple layers | ASA/PMMA+PVC+PVC | 720-1130mm | 2.0-3.0mm | ASS50/30+ACE65/132+ACE51/105 | 350-400kg/h |

| Triple layers | PVC+PVC foamed+PVC | 720-1130mm | 2.0-3.0mm | ACE51/105+ACE65/132+ACE51/105 | 350-400kg/h |

| Four layers | ASA/PMMA+PVC+PVC foamed+PVC | 720-1130mm | 2.0-3.0mm | ASS50/30+ACE51/105+ ACE65/132+ACE51/105 | 350-400kg/h |

Why choose ACEEXTECH:

• Specialized R & D team involved in plastic extrusion industries over 25years.

• Ability to provide the customized plastic extrusion solutions.

• Complete sales system covering the pre-sales, sales and after-sales service jobs.

• Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets.

Our service:

♦ Ability to provide the customized plastic extrusion solutions;

♦ Turn-key solution is pleased to be provided include plant layout and design, formula, production support etc;

♦ Complete sales system covering the pre-sales, sales and after service jobs;

♦ Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets;

♦ Commissioning & installation service in customer plant and free training to client labors.

In order to provide you the specific proposal, please advise:

♦ Basic drawing of final product request to be provided;

♦ Output capacity will be need;

♦ Single or co-extrusion?

♦ How many layers will be?

Contact to ACEEXTECH:

JIANGSU ACEEXTECH MACHINERY CO., LTD

Tel:+86-512 58620105

Fax:+86-512 58620107

Mobile/hatsApp: +86 13962472339

Website:www.aceextech.com

Add:No.18 Yuefeng Road, Nanfeng Town, Zhangjiagang City Jiangsu, China, 215600

• Specialized R & D team involved in plastic extrusion industries over 25years.

• Ability to provide the customized plastic extrusion solutions.

• Complete sales system covering the pre-sales, sales and after-sales service jobs.

• Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets.

Our service:

♦ Ability to provide the customized plastic extrusion solutions;

♦ Turn-key solution is pleased to be provided include plant layout and design, formula, production support etc;

♦ Complete sales system covering the pre-sales, sales and after service jobs;

♦ Professional sales team with local language speaking ability for English, Portuguese, Spanish, Turkish and Russian markets;

♦ Commissioning & installation service in customer plant and free training to client labors.

In order to provide you the specific proposal, please advise:

♦ Basic drawing of final product request to be provided;

♦ Output capacity will be need;

♦ Single or co-extrusion?

♦ How many layers will be?

Contact to ACEEXTECH:

JIANGSU ACEEXTECH MACHINERY CO., LTD

Tel:+86-512 58620105

Fax:+86-512 58620107

Mobile/hatsApp: +86 13962472339

Website:www.aceextech.com

Add:No.18 Yuefeng Road, Nanfeng Town, Zhangjiagang City Jiangsu, China, 215600

ACEEXTECH is a creative company, focusing on R & D of plastic recycling and extrusion system, and providing the equipments and solutions for waste plastic recycling and extrusion.

ACEEXTECH products fulfill the needs of users in a very direct way due to over 25 years of knowledge and experience in plastic recycling and extrusion field, which also helps us to contribute actively to the success of customers by offering sustainable solutions that meet industry needs.

ACEEXTECH offers a complete portfolio of support and consulting services all the time, from project engineering to custom financing solutions, after sales service at its best, ongoing production optimization, training and advisory services, even end product development.

ACEEXTECH products fulfill the needs of users in a very direct way due to over 25 years of knowledge and experience in plastic recycling and extrusion field, which also helps us to contribute actively to the success of customers by offering sustainable solutions that meet industry needs.

ACEEXTECH offers a complete portfolio of support and consulting services all the time, from project engineering to custom financing solutions, after sales service at its best, ongoing production optimization, training and advisory services, even end product development.

More >