Home LED Light Products Black ABS Injected Plastic Hanger

Black ABS Injected Plastic Hanger

| Price: | US $ 0.3/Piece |

|---|---|

| Trade Terms: | FOB,CIF |

| Min Order: | 1000/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal |

| Prod Model: | DF-026 |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Payment Term: | Negotiable |

| Finish Treatment: | as Injected |

| Co: | Zhejiang, China |

Product Description

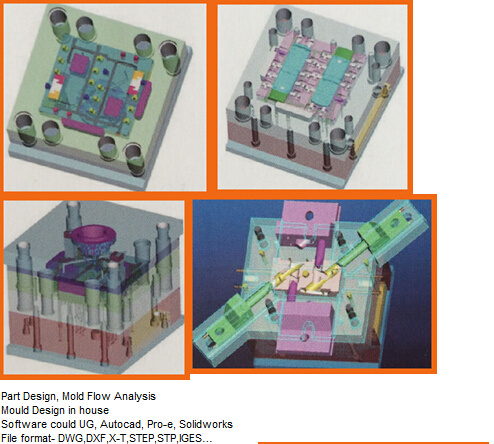

1. Mould Design and Manufacturing by ourselves.

2. Delivery on time

3. Quality system in place

4. OEM and ODM service offered.

5. Some Q and A as below.

| Customer's Question | Our Reply |

| What's the part material that you can work with? | Plastic injection grade, PVC, ABS, PC, PP, POM, PA, PBT with GF or not. |

| Who designs the molds? | Molds design in house. |

| What programs they know? | normally UG. |

| How many molds can they design simultaneously? | Normally, 20 molds per month |

| Can you during the production process make the modification of the existing mold and start the manufacturing again? | Yes, we can modify the molds if the modification is reasonable |

| Have you microwelding for the modification of molds? | Yes, if necessary, we will use welding for mold modification, or make a new insert. |

| Of what materials do you make the main parts of the molds? What is the rigidity? | For the mold core, we use H13, P20, 718, 8402, 8407 etc, hardness about 52HRC. |

| Do you make commercial molds, what materials do you use, what is the rigidity, what is the cost? | Yes, we can make commercial molds per customer's requests, the cost is case by case. |

| What time do you need for the designing and manufacturing of one mold? | Normally 35-60 days for a new mold, depends on the mold size and part geometry. |

| Who makes the molds? | We make the molds. |

| Describe the structure of the production, how many molds can they make simultaneously? | Normally, develop 15-20 new molds per month |

| What equipment have they, how many units? | from 18 ton- 2000Ton |

| How many work places are there in the shop? | We have 4 building for the workshop about 6,600 square meters. |

| Who makes the plastic parts? | We make the plastic parts. |

| Can you make small batches of experimental parts in the quantity to 1000 pcs? | Yes, we can make small batch, like 1,000pcs. |

| Can you work with Chinese molds, made at another enterprise? | 1. Need to see if the mold by other Chinese enterprise is in good condition. 2. Will charge cost if we need to repair the tool. |

| Can you make prototypes of plastic parts according to our drawings 3D Solid by means of the following technologies: CNC of PC natural and transparent, CNC of PC natural with painting, CNC of ABS | Yes, we can do. 2 they're prototypes for both PC and aluminum |

| What is the precision at the manufacturing by means of CNC technology? | By CNC to make prototypes, normal precision is +/-0.10mm |

| Do you polish the transparent parts? | For transparent prototypes, we do polish or apply texture. For production of transparent parts, we make it by injection molding directly. |

| SLA. What is the precision, what is the material? | The SLA we talk is 3d printing, use light-sensitive resin, made in China, precision is +/-0.10mm. |

| Can you make prototypes in silicone molds? | We can make prototypes in silicone molds |

| Mould Life | 100K- to 150K shots |

| Packing material | Wooden box |

| Hot Runner | HASCO, DME etc. |

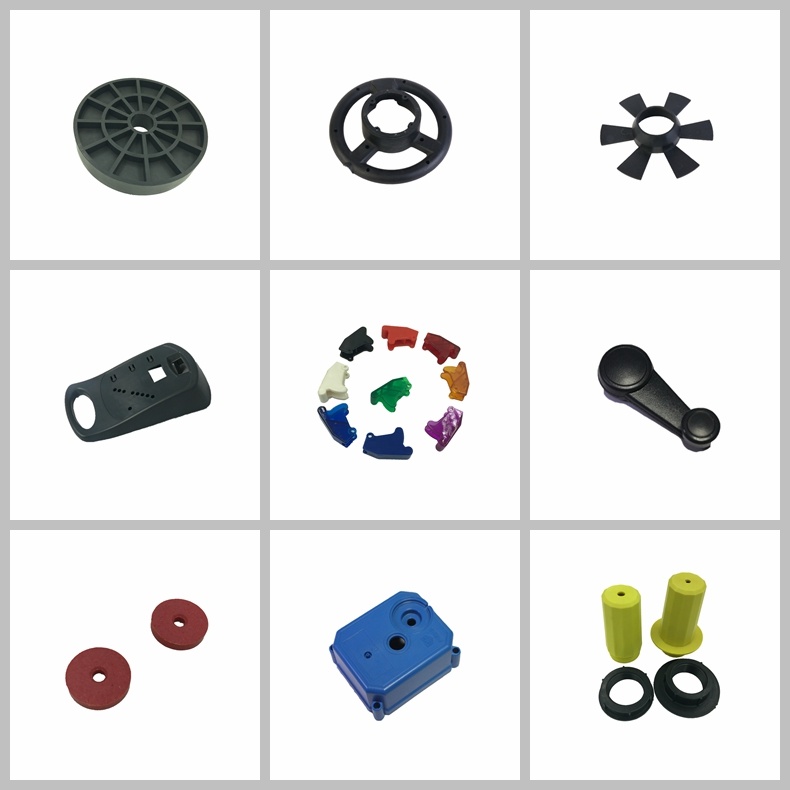

We're professional maker for plastic parts and injection molds, able to provide custom manufacturing services from Prototype to Production.

It covers an area of 6600 square meters, building area of 3800 square meters. There are injection molding workshop, tooling workshop, and secondary processing workshop, ISO 9001 was certified.

All kinds of size 35 sets of Haitian injection molding machine, largest one is 450 Tons, the minimum tonnage is 38Tons.

In house mold making equipments include: Milling machine, grinding machine, drill machine, slow feed wire cutting machine, EDMs. Inspection equipments include hardness tester, depth tester, height gauge, two-dimension measuring instrument, and UL94-V0 testing machine.

Single or multiple cavity mold making capabilities.

Capability to handle all grades of plastic.

Low & high volume production.

Capability to finish the ultrasonic welding, silk screen, pad screen, and assembly.

In our company, we remain customer-oriented and understand quality comes first. We understand the importance of service, convenience, quick response, responsibility and trust all customers expect.

We're a finished OEM parts manufacturer, whose main parts are plastic injection parts and moulds, we're pleased to offer OEM service and sub-assembly service for our overseas customers.

1. Advantage

OEM and ODM service

Apperance and precise engineering parts

High and low volume

Sub-assembly service

2. Production capability

Injection mould development in house, injection moulding service in house, sub-assembly service.

3. Material availability

ABS, PC, PP, POM, PA, PE, PC+ABS, TPE, multiple material available.

4. Finish availability

Wet painting, chrome plating, silk and pad printing, heat staking, ultrosonic welding.

5. IPQC

IPQC through the whole molding process, spot inspection for material coming-in, spot inspection for molding process and final inspection based on AQL.

6. Delivery on time

7. Real time Skype support

It covers an area of 6600 square meters, building area of 3800 square meters. There are injection molding workshop, tooling workshop, and secondary processing workshop, ISO 9001 was certified.

All kinds of size 35 sets of Haitian injection molding machine, largest one is 450 Tons, the minimum tonnage is 38Tons.

In house mold making equipments include: Milling machine, grinding machine, drill machine, slow feed wire cutting machine, EDMs. Inspection equipments include hardness tester, depth tester, height gauge, two-dimension measuring instrument, and UL94-V0 testing machine.

Single or multiple cavity mold making capabilities.

Capability to handle all grades of plastic.

Low & high volume production.

Capability to finish the ultrasonic welding, silk screen, pad screen, and assembly.

In our company, we remain customer-oriented and understand quality comes first. We understand the importance of service, convenience, quick response, responsibility and trust all customers expect.

We're a finished OEM parts manufacturer, whose main parts are plastic injection parts and moulds, we're pleased to offer OEM service and sub-assembly service for our overseas customers.

1. Advantage

OEM and ODM service

Apperance and precise engineering parts

High and low volume

Sub-assembly service

2. Production capability

Injection mould development in house, injection moulding service in house, sub-assembly service.

3. Material availability

ABS, PC, PP, POM, PA, PE, PC+ABS, TPE, multiple material available.

4. Finish availability

Wet painting, chrome plating, silk and pad printing, heat staking, ultrosonic welding.

5. IPQC

IPQC through the whole molding process, spot inspection for material coming-in, spot inspection for molding process and final inspection based on AQL.

6. Delivery on time

7. Real time Skype support