Home LED Light Products Clothes Hanger Plastic Making Machine

Clothes Hanger Plastic Making Machine

| Price: | US $ 16200/Piece |

|---|---|

| Trade Terms: | FOB,CIF |

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T,Western Union |

| Prod Model: | BST-1000A |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Name: | Clothes Hanger Plastic Making Machine |

| Screw Diameter: | 36-38mm |

| Shot Size: | 143-180cm³ |

| Shot Weight: | 128-162g |

| Injection Pressure: | 164-183MPa |

| Injection Rate: | 90-98g |

| Screw L/D Ratio: | 20.5-21.6 |

| Screw Speed: | 0-190 |

| Nozzle Diameter: | 10 |

| Clamp Tonnage: | 1000kn |

| Type: | Preform Injection |

| Structure: | Horizontal |

| Plastic Type: | Thermoplastic |

| Plasticizing Way: | Screw Type |

| Clamping Way: | Hydraulic |

| Automation: | Automatic |

| Computerized: | Computerized |

| Certification: | ISO9001:2008 |

Product Description

Clothes Hanger Plastic Making Machine

Specifications

Injection molding machine

1.Big tie bar space and shot weight capacity

2.Most famous component parts

3.Perfect after-service

FEATURES

- A variety of text can be switched.

- Manual, semi-automatic and fully automatic mode.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement

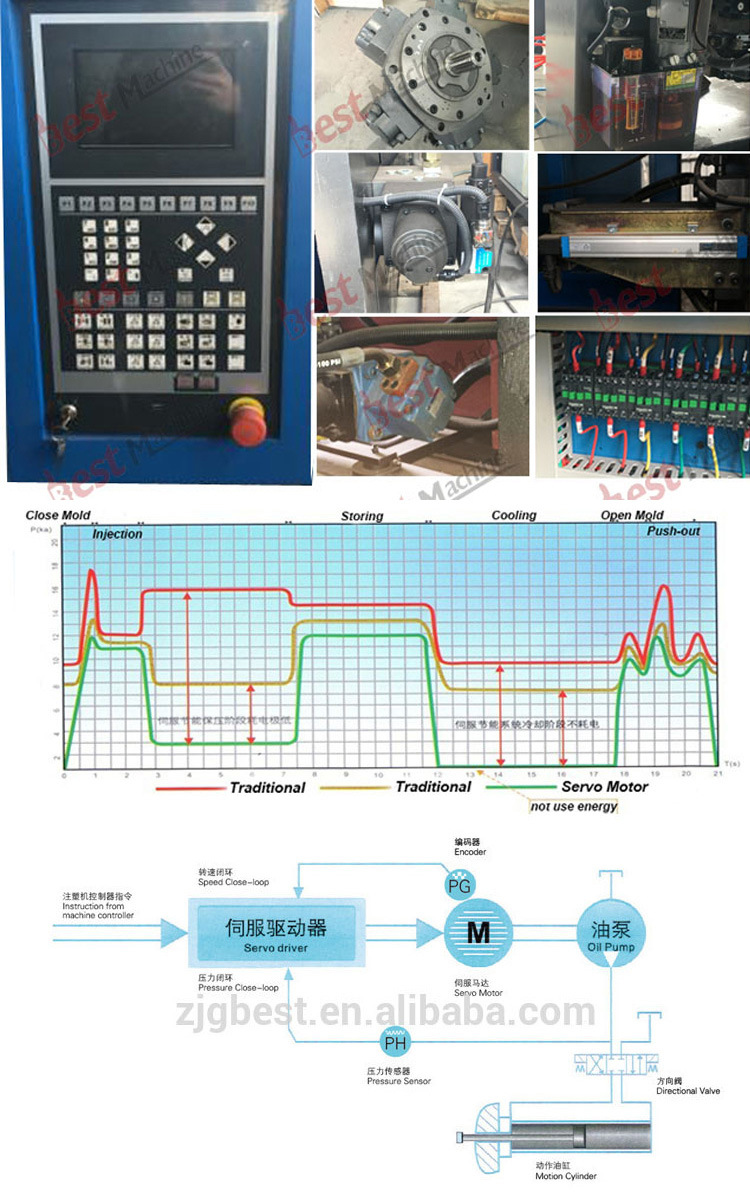

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and

with a number of peripheral interfaces.

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

SERVO SYSTEM

After receiving the pressure and flow instruction from computer controller, the servo driver will compare it with the actual pressure and flow feedback, and rectify the difference by controlling the rotating speed of the servo motor. In this way, the control of injection molding is not only acurate but also fast, and the repeatabillity of the products high as well.

Technical parameters

| MODEL | BST-1000A | ||||||

| INJECTION UNIT | A | B | |||||

| Screw diameter | mm | 36 | 38 | ||||

| Shot size(theoretical) | Cm³ | 143 | 180 | ||||

| Shot weight | g | 128 | 162 | ||||

| Injection pressure | Mpa | 183 | 164 | ||||

| Injection rate | g/s | 90 | 98 | ||||

| Screw L/D ratio | L/D | 21.6 | 20.5 | ||||

| Screw speed | r.p.m | 0-190 | |||||

| Nozzle Diameter | Srmm | 10 | |||||

| CLAMPING | |||||||

| Clamp tonnage | KN | 1000 | |||||

| Toggle stroke | mm | 320 | |||||

| Mould Thickness | mm | 150-400 | |||||

| Space between tie-bars | mm | 385X350 | |||||

| Ejector stroke | mm | 125 | |||||

| Ejector tonnage | KN | 50 | |||||

| Ejector number | Piece | 5 | |||||

| Hole Diameter | mm | 100 | |||||

| OTHERS | |||||||

| Heat power | KW | 7.6 | |||||

| Max. pump pressure | MPa | 16 | |||||

| Pump motor power | KW | 11 | |||||

| Valve Size | mm | 10 | |||||

| Machine dimension | m | 4.3X1.5X1.6 | |||||

| Machine weight | t | 3.4 | |||||

| Oil tank capacity | L | 180 | |||||

Our Service

Supply mode: the supplier factory delivery, simple packaging, the supplier agent consignments, the expense is payed by the buyer .

Terms of payment: the buyer pay 30% of the total payment as the signing of the deposit, the contract comes into effect, pay the balance before shipment .

Quality assurance: the equipment according to the enterprise standard implementation and mechanical guarantee period is one year, the main electrical appliances for half a year .

Method of acceptance: equipment processing after the completion of delivery, the buyer sent to the factory acceptance, for commissioning, the buyer to provide raw materials for plastic material .

Technical and after-sales service:

The supplier the following technical and after-sales service commitment

A) provide on-site installation guide;

B) responsible for the commissioning of equipment;

C) responsible for the buyer's personnel mount guard before the operation and maintenance training;

D) one year free warranty (due to the buyer's improper operation caused by damage charge costs), and ensure the supply of spare parts for a long time, only receive the cost.

E) provide technical advisory services for a long time

Delivery date: the contract is signed and completed within 45 working days after receiving the deposit unit processing and manufacturing, with the conditions of the factory acceptance

Zhangjiagang BeST machinery Co., Ltd

Is located in a beautiful development zone in Tangqiao, Zhangjiagang City, Jiangsu Province, China

Line

Company is very professional in research, development, manufacturing of all kinds plastic machinery and moulds,

With more than 3, 000 million fixed assets, during the past 19 years, we always force our energy into new areas of

Plastic packaging machinery, to update the technology, to learn advanced experience, to confirm new theory and

New design, we are forming a unique competitive advantage of our owns.

The machcines from our company carry good quality and effective after-sales service, upon the domestic market,

We hotly export machines to Russia, South Africa, Vietnam, Ethiopia, Saudi Arabia, Malaysia, Canada, Algeria,

Uzbekistan and many other countries, create good sales performance and well feedback, all to strengthen our

Position in this field.

With full enthusiasm, serious attitude and win-win business conception, welcome you to become our clients! !

Is located in a beautiful development zone in Tangqiao, Zhangjiagang City, Jiangsu Province, China

Line

Company is very professional in research, development, manufacturing of all kinds plastic machinery and moulds,

With more than 3, 000 million fixed assets, during the past 19 years, we always force our energy into new areas of

Plastic packaging machinery, to update the technology, to learn advanced experience, to confirm new theory and

New design, we are forming a unique competitive advantage of our owns.

The machcines from our company carry good quality and effective after-sales service, upon the domestic market,

We hotly export machines to Russia, South Africa, Vietnam, Ethiopia, Saudi Arabia, Malaysia, Canada, Algeria,

Uzbekistan and many other countries, create good sales performance and well feedback, all to strengthen our

Position in this field.

With full enthusiasm, serious attitude and win-win business conception, welcome you to become our clients! !