Home LED Light Products Custom Plastic Part Hanger Guar

Custom Plastic Part Hanger Guar

| Price: | US $ 0.15/Piece |

|---|---|

| Min Order: | 50/Piece |

| Pay Type: | L/C,T/T |

| Prod Model: | DML160624 |

|---|---|

| Material: | ABS |

| Color: | Black, Red, Green, Yellow, Transparent |

| Weight: | From 0.1grams to 12 000grams |

| Feature: | UV, Oil, Heat Resistant;Abrasion, Aging Resistan |

| Finish: | Smooth, Matt, Chromate Plating or Any Oth |

| Size: | Customized, Per Your Design |

| Temperature: | -40c-260c( or Per Your Required |

| Tolerance: | International Standard, or Per Your Required |

| Custom Logo: | Embossed or Debossed Logo on Tooling or Silk Print |

Product Description

Custom Injection moulding with Plastic Injection Mould1. Basic Information

Mold type: all tyes of produts plastic mould

Mould base material: #45.LKM, LYM standard etc

Mould spare parts material: Jinghong, HASCO, DME etc

Hardness of steel: 28-50HRC

Mould design: 3D/2D drawings

Runner: cold runner

Design days: 1-3days

Mould life: 500,000-3,000,000 shots

Plastic material: PE, PC, PS, PP, PA, ABS, etc

Injection system : pin point gate

2. Quality Reference

Level A: 1,000,000 shots - high

Level B: 800,000 shots - middle

Level C: 500,000 shots - normal

3. Application

Communication/Electronic/Auto parts/Surveillance products/Medical device/equipment and so on .

4. Customers assistance for initial detailed quotation on plastic injection molding

1) 2D/3D Design drawings offered

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material information

4) Level and quantity information if possible.

Injection Moulding

Our mouldshop has the latest semi-automatic moulding machines for small to medium sized production runs, along with a fully automated facility to accommodate customers with high volume requirements. This gives us the ability to produce virtually any quantity from one to one million plus.

We only use materials from official distributors which helps us provide consistent product and material traceability. As a result we have a wealth of materials to choose from and can offer advice on selection for your particular application.

Please feel free to contact us regarding your injection moulding requirements here.

Facilities we provide

Low volume production runs

BOY auto and semi auto machines

Advice on process materials

Full insert & overmould capability

ISO 9001:2008 accreditation

Extensive material knowledge

Two-shot moulding

Material Expertise

The materials that we use and are experienced in, include most general purpose and engineering grades such as;

ABS

Nylon

Acetal

PPS (high temp)

ABS/Polycarbonate alloys

TPE (medical grade USP class 6)

plastic auto parts injection mould

| Product Name | plastic auto parts injection mould |

| Plastic Material | ABS, PP, PBT, PC, PBT+GF30%, .POM etc |

| Mould Material | P20. 718,1.2738 ,1.2711 ,P20HH ,S136 etc. |

| Size | 80T-2500T |

| No. of Cavity | Single / Muti |

| Runner | Hot/ Cold |

| Surface Finish | polishing, sand blasting, Graining,IMD ,paiting |

| Precision | 0.005mm-0.002mm |

| Mould Life | 300K~1000K Shots |

| Certificated | ISO9001:2008; TS16949 |

| Lead Time | 25-60 days |

| Annual Output | 300 sets of mold |

| Trade Terms | FOB,EXW,CIF |

| FOB Price | US $ 2000 - USD$200,000 / set |

| Payment term | T/T, L/C, paypal |

| Payment condition | 50% deposit in advance, balance 50% after sample confirmed( According to agreement with customer) |

| Package | Wooden case |

| Supply Ability | 30 Set/Sets per Month |

| Port of loading | Shenzhen |

| Offer OEM/OED | Yes |

| How to order Plastic Injection Mould |

| 1.Quote | According to samples, 2/3 D drawing and specification | |

| ↓ | ||

| 2.Discussion | Mould core/base material, cavity number, runner type, price, payment, etc | |

| ↓ | ||

| 3.PI | Approval for all terms | |

| ↓ | ||

| 4. Deposit | 50% by T/T | |

| ↓ | ||

| 5.Product Design | Our engineer will check product drawing, and pick up the unreasonable terms | |

| ↓ | ||

| 6.Mould Design | Our engineer will do DFM and send PPT to customers for approval | |

| ↓ | ||

| 7.Mould making | We start to make mould after customers confirmed the drawing | |

| ↓ | ||

| 8.Mold Testing | We will express trial samples to customers by DHL for confirmation | |

| ↓ | ||

| 9. Mould repair | We will modify the mould according to customer's feedback | |

| ↓ | ||

| 10. Mould approval | Express trial samples by DHL again till products approval | |

| ↓ | ||

| 11.Balance payment | 30%-50% by T/T before delivery | |

| ↓ | ||

| 12.Delivery | Delivery by sea or air, all documents as customer required | |

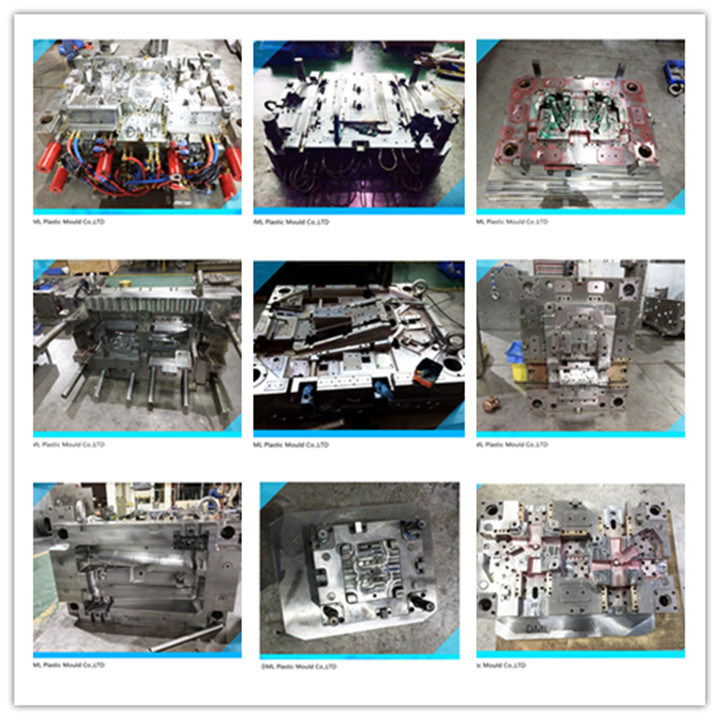

Plastic Injection Mould product

Our factory

DML PLASTIC MOULD CO., LIMITED

DML Plastic Mould Factory was established in Hong Kong in year of 2001 and set up factory in Dongguan China.

DML Plastic Industrial is providing both moulds and molding service for various industries including household appliance, automotive parts and accessories, kitchen wares, traveling apparatus, sports instruments, etc. And its facility has exceeded 3000 square-meters while employees in service amount to more than 200.

Its molds and products have been sold very well all over the world, especially in European countries and U. S., due to its competitive price, on-time delivery and high quality. And DML have always earned a good reputation as "ship-stock" supplier, which should be attributed to its up-to-date precise facilities, experienced engineering teams and trained workers, professional managing team, and all available sources.

FAQ

Q1. Can I have a mold manufacturers sample order for your products?

A: Yes, we welcome sample order to test and check quality. Mixed mold manufacturers samples are acceptable.

The charge will be returned when your order reaches the target quantity.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs3-4 weeks for order quantity.

Q3. Do you offer guarantee for the products?

A: Yes,we offer 2-3 years warranty of our products and we assure quality of your order same

as the samples and delivery would stricktly follow the agreement.

Q4: Is it OK to print my logo on led light product?

A: Yes,please inform us formally before our production and confirm the design firstly based on our sample.

Q5:Can you provide more pictures & details of the product so that i

introduce to my customer?

A: Yes, please contact our sales for more information.

Q6: How should I pay for you if I place order to you?

A:Usually,Payment by T/T ,L/C,small order 100% in advance; large order 30% deposit in advance and 70% balance before delivery.Please discuss the details with sales.

DML Plastic Mould Factory was established in Hong Kong in year of 2001 and set up factory in Dongguan China.

DML Plastic Industrial is providing both moulds and molding service for various industries including household appliance, automotive parts and accessories, kitchen wares, traveling apparatus, sports instruments, etc. And its facility has exceeded 3000 square-meters while employees in service amount to more than 200.

Its molds and products have been sold very well all over the world, especially in European countries and U. S., due to its competitive price, on-time delivery and high quality. And DML have always earned a good reputation as "ship-stock" supplier, which should be attributed to its up-to-date precise facilities, experienced engineering teams and trained workers, professional managing team, and all available sources.

In order to optimize the productivity of each mold produced, during the mold design stage, an optimal structure design of mold will be determined by the team leaders of our designing, engineering, and production team in numbers of discussions. This proposed design would only be executed upon approval of the mold shop manager. Aided by a series of computer software, mold designers are able to finish a full set of mold structure drawings precisely and rapidly.

In the mold-making stage, every single process of each mold component must pass the quality inspection until all processes are completed.

However, an entire re-inspection of all data and workmanship of all components must pass prior to mold-assembly for quality assurance of each mold produced.

A spacious and well-equipped dust-free production environment with various type of injection molding machines (includes dual injection molding machines) and supplementary facilities to cope up with extensive customer needs.

A series of environmentally friendly product cosmetic facilities---from spray-printing, pad-printing, silk-screen printing, bristle implantation to conveyor assembly lines for OEM products, composed with a full inspection procedure on all in-process products are done prior to final packing that would raise customer satisfaction and confidence for our product services.

Quality-"Essence of Product, Lifeline of Enterprise". DML always treat quality as priority task. In order to ensure the quality of products and to preserve customer commitment, a rigorous and well-tailored inspection procedure from are able to fulfill customer's production specification requirements. For the years of quality commitment leads DML to ISO9001 recognition.

In order to enhance the concept and importance of ISO9001 and professionals are invited occasionally to train all staffs and aiming to achieve ISO9001.

DML Plastic Industrial is providing both moulds and molding service for various industries including household appliance, automotive parts and accessories, kitchen wares, traveling apparatus, sports instruments, etc. And its facility has exceeded 3000 square-meters while employees in service amount to more than 200.

Its molds and products have been sold very well all over the world, especially in European countries and U. S., due to its competitive price, on-time delivery and high quality. And DML have always earned a good reputation as "ship-stock" supplier, which should be attributed to its up-to-date precise facilities, experienced engineering teams and trained workers, professional managing team, and all available sources.

In order to optimize the productivity of each mold produced, during the mold design stage, an optimal structure design of mold will be determined by the team leaders of our designing, engineering, and production team in numbers of discussions. This proposed design would only be executed upon approval of the mold shop manager. Aided by a series of computer software, mold designers are able to finish a full set of mold structure drawings precisely and rapidly.

In the mold-making stage, every single process of each mold component must pass the quality inspection until all processes are completed.

However, an entire re-inspection of all data and workmanship of all components must pass prior to mold-assembly for quality assurance of each mold produced.

A spacious and well-equipped dust-free production environment with various type of injection molding machines (includes dual injection molding machines) and supplementary facilities to cope up with extensive customer needs.

A series of environmentally friendly product cosmetic facilities---from spray-printing, pad-printing, silk-screen printing, bristle implantation to conveyor assembly lines for OEM products, composed with a full inspection procedure on all in-process products are done prior to final packing that would raise customer satisfaction and confidence for our product services.

Quality-"Essence of Product, Lifeline of Enterprise". DML always treat quality as priority task. In order to ensure the quality of products and to preserve customer commitment, a rigorous and well-tailored inspection procedure from are able to fulfill customer's production specification requirements. For the years of quality commitment leads DML to ISO9001 recognition.

In order to enhance the concept and importance of ISO9001 and professionals are invited occasionally to train all staffs and aiming to achieve ISO9001.

More >