Home LED Light Products Drawn-Cup Needle Roller Bearings for Compressor

Drawn-Cup Needle Roller Bearings for Compressor

| Price: | US $ 2.2-2.8/Piece |

|---|---|

| Min Order: | 500/Piece |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: | CIE-DC-012 |

|---|

Product Description

Drawn Cup Roller Clutch Bearings (One-way Bearing)High durability under the alternative coolant(non-Freon type)and high rotating speed.

The outer ring with large load carrying capacity of drawn cup needle roller bearing is formed by punching the thin steel plate. It is suitable for small section height, or when the housing bore isn't used for raceway, this type is recommended to use. The bearing is assembled into the housing bore under a certain pressure without further axial orientation.

Usually this type needn't use inner ring, but if needed, you can obtain some information form this catalogue. In contract to the drawn cup needle roller bearing with open end, the bearing with one closed end has good sealing properties. Unsealed drawn cup needle roller bearing is available for temperature between -20 degree and +120degree with high quality lithium base grease.

High durability under the alternative coolant (non-Freon type)and high rotating speed.

Needle Roller Clutch with Pressed Outer Ring (unilateral bearing) can be treated as converter, non-return device, free wheel device. HF (Needle Roller Clutch): it is made of pressed outer ring and plastic holder; the holder can be installed with plastic reed or the stainless steel reed to guide the needle rollers, bevel race way and needle rollers can be treated as locking device. HFL(Clutch and Bearing Unit): pedestal bearing is installed at the two sides of the needle roller clutch and bears the radial load, the needle roller and the plastic holder units can be treated as the pedestal bearing.

| Bearing No. | Characteristics of Structure |

| HF | Needle Roller Clutch with Pressed Outer Ring and Steel Spring |

| HF..KF | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Plastic Spring |

| HF..R | Needle Roller Clutch with Pressed Outer Ring and Steel Spring, Knurling Outer Ring |

| HF..KFR | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Plastic Spring, Knurling Outer Ring |

| HFL | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Steel Spring, Sliding Bearing or Rolling Bearing |

HFL..KF | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Plastic Spring, Sliding Bearing or Rolling Bearing |

| HFL..R | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Steel Spring, Knurling Outer Ring |

| HFL..KFR | Needle Roller Clutch and Bearing Units with Pressed Outer Ring and Plastic Spring, Knurling Outer Ring |

note1 Unidirectional bearing''s Maintains frame all is Nylon material KF means the Reeds on Maintains frame are Nylon material without KF means the Reeds are Stainless steel note2 R means bearing addendum circle knurling to increases nips the joint effort;

(2)in order to make Roller pin in Is in as necessary locks the position Maintains the frame to have the stainless steel reed Limit rotational speed are Effective on Fat and oil lubrication,Width deviation -0mm -0.25mm, special request When ordering explained. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

If there is any question of stamped cup roller clutch bearings on automotive line, welcome to contact us in details

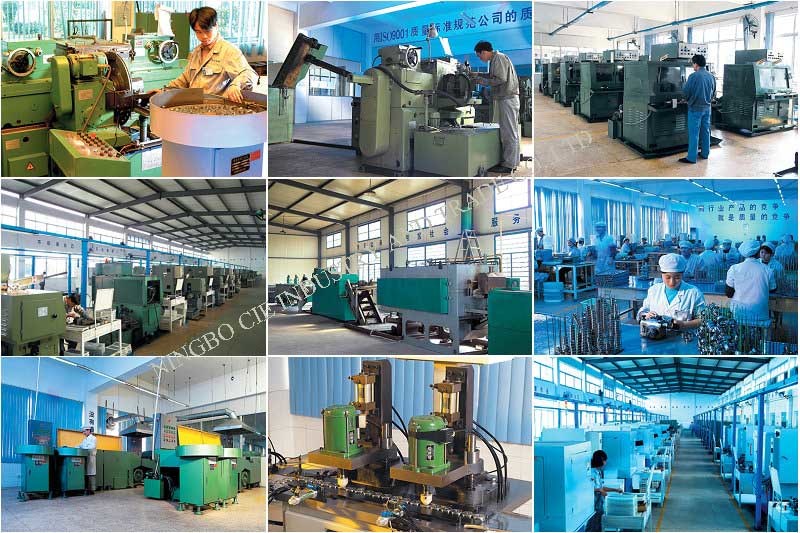

Our Workroom, Test Lab and Fair Booth at a glance:

INGBO CIE INDUSTRY AND TRADE Co., Ltd was established from 1988 in China and export more than 30 years old mainly for Industrial bearing Our Head Company registered capital is USD1, 500, 000, and we have 1, 200 employees contributing to the turnover of more than 0.8 billion US dollars.

We have passed the evaluations of ISO9001: 2001 quality management system, ISO14001: 2004 environment management system and OHSAS18001: 1999 certification. We possess more than ten subsidiary companies, an industrial zone named CIE Industry occupying 25, 000 square meters, and more than ten manufacturing factories respectively engaged in high quality automotive parts and bearings, including automotive wheel bearings and kits, auto bearings, automotive bearings, wheel-hub units and kits, air-conditioner compressor bearings, steering-gear bearings, deep groove ball bearings, tapered roller bearings, needle roller bearings and special non-standard bearings, ball screw, linear guide rail and block assembly, steering systems with power steering gear, manual steering gears like recirculating balls and nut steering gears, racks and pinion steering gears, steering columns, steering linkages, as well as steering gearbox parts like gear sector shafts, worm assemblies and ball screws, linear guide rails and block systems. You can find our products installed as OEM equipment in automobiles from Europe, Asia and the U. S. A.

Our subsidiary company-CIE Auto Source Industry Co., Ltd. Was established in 1996, and is strong at the production of bearings, Power Transmission Parts and Steering System, of which the details focus on the following issues:

Design strength:

Our in-house team of approximately 60 experienced engineers is constantly developing newer and better bearing models, and auto parts mainly for steering systems. The most advanced computer aided design (CAD) systems and Germany-imported grinder machines are utilized to incorporate your specific requirements. Our ratio of R&D investment is much higher than the average in domestic industry.

Quality control:

Some of our QC instruments and meters are imported from Japan and Germany. We inspect every item with Talyrond roundness testing instruments before packaging. Our team also performs noise and vibration tests as well as radial and axial clearance inspection. Steering system parts are inspected on fatigue test bench, metering inspection center, 3D measuring apparatus, performance test bench and alignment test bench.

Services:

We are committed to providing first class services and top quality products through:

1)Developing trading relationships of mutual trust with customers and suppliers;

2)Training and development of all our employees to enable them to release their full potentials and provide career progression;

3)Supporting objectives which safeguard the environment, leading to better working practices and safety running of machine and operation;

4)Improving efficiency by incorporating technological solutions

5)Exceeding customer's expectation for service, quality and value for money\

6)Improving communications with our customers, suppliers and staff to keep them up to date with industrial development and news

Constantly contacting customers for product's further development is given higher priority at NINGBO CIE INDUSTRY AND TRADE Co., Ltd., and serious development work relies on knowing the demands and requirements of the market.

We have passed the evaluations of ISO9001: 2001 quality management system, ISO14001: 2004 environment management system and OHSAS18001: 1999 certification. We possess more than ten subsidiary companies, an industrial zone named CIE Industry occupying 25, 000 square meters, and more than ten manufacturing factories respectively engaged in high quality automotive parts and bearings, including automotive wheel bearings and kits, auto bearings, automotive bearings, wheel-hub units and kits, air-conditioner compressor bearings, steering-gear bearings, deep groove ball bearings, tapered roller bearings, needle roller bearings and special non-standard bearings, ball screw, linear guide rail and block assembly, steering systems with power steering gear, manual steering gears like recirculating balls and nut steering gears, racks and pinion steering gears, steering columns, steering linkages, as well as steering gearbox parts like gear sector shafts, worm assemblies and ball screws, linear guide rails and block systems. You can find our products installed as OEM equipment in automobiles from Europe, Asia and the U. S. A.

Our subsidiary company-CIE Auto Source Industry Co., Ltd. Was established in 1996, and is strong at the production of bearings, Power Transmission Parts and Steering System, of which the details focus on the following issues:

Design strength:

Our in-house team of approximately 60 experienced engineers is constantly developing newer and better bearing models, and auto parts mainly for steering systems. The most advanced computer aided design (CAD) systems and Germany-imported grinder machines are utilized to incorporate your specific requirements. Our ratio of R&D investment is much higher than the average in domestic industry.

Quality control:

Some of our QC instruments and meters are imported from Japan and Germany. We inspect every item with Talyrond roundness testing instruments before packaging. Our team also performs noise and vibration tests as well as radial and axial clearance inspection. Steering system parts are inspected on fatigue test bench, metering inspection center, 3D measuring apparatus, performance test bench and alignment test bench.

Services:

We are committed to providing first class services and top quality products through:

1)Developing trading relationships of mutual trust with customers and suppliers;

2)Training and development of all our employees to enable them to release their full potentials and provide career progression;

3)Supporting objectives which safeguard the environment, leading to better working practices and safety running of machine and operation;

4)Improving efficiency by incorporating technological solutions

5)Exceeding customer's expectation for service, quality and value for money\

6)Improving communications with our customers, suppliers and staff to keep them up to date with industrial development and news

Constantly contacting customers for product's further development is given higher priority at NINGBO CIE INDUSTRY AND TRADE Co., Ltd., and serious development work relies on knowing the demands and requirements of the market.

More >