Home LED Light Products Glass Candle Jar/Glass Candle Holder/Glass Mason Jar

Glass Candle Jar/Glass Candle Holder/Glass Mason Jar

| Price: | US $ 0.2/Piece |

|---|---|

| Min Order: | 30000/Piece |

| Pay Type: | L/C,T/T |

| Prod Model: | 330ml, 500ml, 750ml, 1L |

|---|---|

| Volume: | 500-1000 Ml |

| Material: | Glass |

| Sealing Type: | Screw Cap |

| Bottleneck: | Narrow Mouth Bottle |

| Shape: | Round |

| Age Group: | Adult |

| Color: | Color |

| Feature: | Disposable |

| Application: | Pharmaceutical |

| Surface Handling: | Screen Printing |

Product Description

China Manufacturer of quality glass bottle,offering custom design glass bottles for spirits,wine,beer,water,food,cosmetics,etcGlass Food Jar/Mason Jar with lid

Glass candle jar

Features

1. Material: Dark Green, Antique Green, Flint

2. Decoration for glass bottles such as decal, silk printing, frosted finish, film and color spray-painting,engraving mark and gold plating,etc.; we can also offer medium-to-high grade carton packaging.

3.Customer design available

Products Discription:

| Material : | Dark green or antique green |

| Production : | Machine made |

| Capacity: | Various glass customer specific designs |

| Sealing Type: | Screw cap or Cork |

| Standard Glass Bottle MOQ | 30,000pcs |

| Decoration on bottle: | 1.Color coating 2.Frosted 3. Decaling 4.Silkscreen printing 5.Gold plating ,etc |

| Packaging | Bulk pallet packed or carton packed |

| Sample lead time | 21 days |

| Prodction mold lead time | 21 days |

| Payment term: | T/T |

| Others: | Cap and cork can also be supplied |

| Certificate: | SGS, FDA, ISO9001 |

| Place of Origin | Qingdao, China(Mainland) |

OUR KEY ADVANTAGE

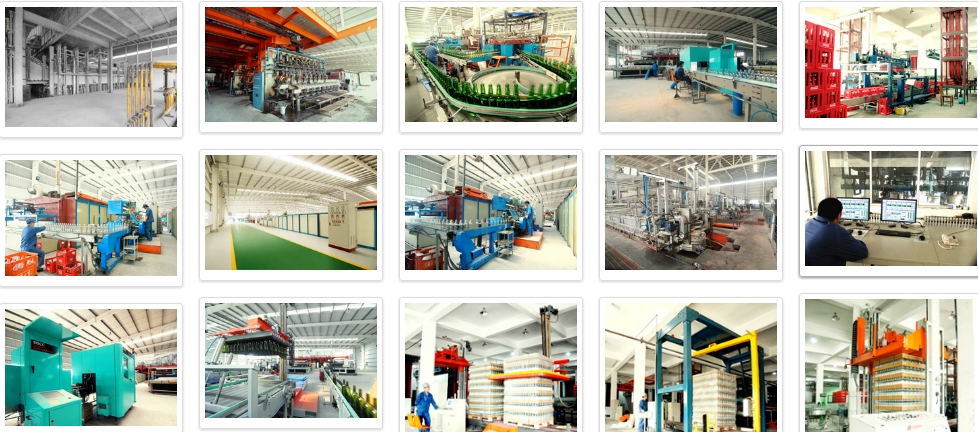

1.Strong manufacturing capacity and high standard quality control

With an installed capacity of 2,280 tonnes per day, makes us able to produce glass bottles and containers in flint, superflint, green, amber color.

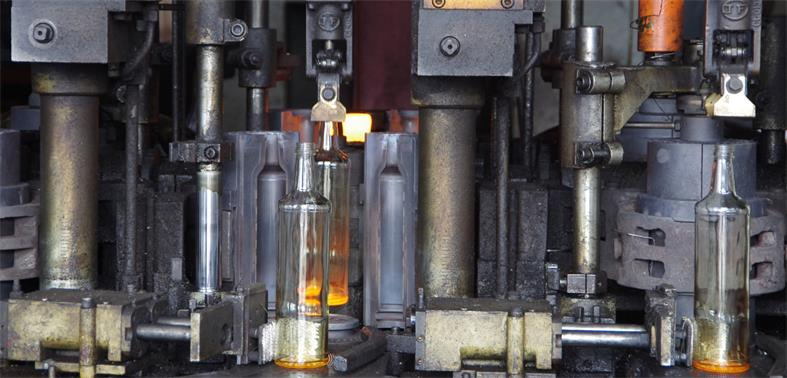

QC,first happens at the IS machine, immediately after the bottle is formed. Here, the line operator, with the quality control checker, does hot end sampling for dimensional checks.

Hot-end ware rejection is an automatic process to ensure quality of the bottles after bottle swabbing. Next, the bottles are put into an annealing chamber, where they are gradually heated and cooled to de-stress.

The bottles then pass through a series of automatic and camera inspection checks by equipment like M, M-Cal, Veritas and VISIGLAS. These machines check for body defects, neck finish, bubbles, foreign matter etc.

The bottles are finally automatically shrink-wrapped, and a sample of the packed bottles is put through a QA process to check for defects.

There are two different types of flint quality glass

Super Flint extra clear glass, used for the production of bottles for Ultra Premium brands with retail price over 30 USD per bottle. Super Flint glass bottles give an ultimate look to your product and make it stand out on the shelf.

Flint clear glass, usually used for Mid-Premium brands.

2.DESIGN & ENGINEERING

Because each project is unique, the UNIPACKGLASS makes a dedicated project team. DESIGN & ENGINEERING,who specializing in bottle and brand design from scratch, and the 3D PRINT PROTOTYPING which can rapid prototyping capabilities in-house.

3.Price of mass production private mold from 3,000 USD

In Europe and USA production of a private mold costs a fortune, sometimes reaching the level of 25,000 USD per mold set. However, due to lower labor costs and flexible production, here in China we set the record minimum price starting at 3,000 USD per mold set. Our molds can produce millions of bottles and whenever they wear out we replace the mold with new one free of charge. The cost of mold is refundable after 500,000 bottles ordered.

4.Minimum order quantity for custom design bottles only 30,000 bottles

In UNIPCKGLASS the MOQ requirements for exclusive bottles, only 30,000 bottles per run. That gives a great opportunity for the start ups and new projects to make a test run in the alcohol market.

5.Only 30 days from concept design to bottle mass production

5.Only 30 days from concept design to bottle mass production

Due to our flexibility and speed of operations we manage to do the efficient work in much shorter period of time, which saves our clients a great deal of time and money.

6.Significant cost advantages

Though the manufacturing of glass itself is highly automated, critical functions such as quality control need large teams of skilled professionals. Not surprisingly, the total cost of production in China, where manpower is among the cheapest in the world, is less than half of that in France and almost half of that in the US. With manufacturing facilities in North China,Unipack Glass is able to produce glass at significantly lower costs than its competitors in other parts of the world and deliver a sustainable cost advantage to customers.

7.Decoration services and accessories

Equipped with 4 American STRUTZ3 high-speed printers,2 Netherlands ROSARIO3 printer, 1 Italian automatic RB-4/6 six-color printer and 6 automatic packaging lines, enable us to make the high quality decoration of the bottles. At the same time we also have lines as decal, frosting , gold plating that can meet the specific requirements of our customers needs.

Established back in the year 1980, Unipack glass producing high quality and most exclusive glass bottles for beer, wine, spirits, food, non-alcoholic beverages, cosmetics and pharmaceuticals.

As one of the leading glass manufacturer in North China, we offer one-stop- shop packaging solutions, include full bottle design capabilities, in-house mould design, CNC machines for mould manufacturing, high quality glass manufacturing and dedicated ancillaries for decoration and accessories like caps, cartons and labels

Unipack Glass offers several competitive advantages over other suppliers include:

Strong manufacturing capacity and high standard quality control

With an installed capacity of 2, 280 tonnes per day, makes us able to produce glass bottles and containers in flint, super flint, green, amber color.

At Unipack glass, quality is of paramount importance.

First happens at the IS machine, immediately after the bottle is formed. Here, the line operator, with the quality control checker, does hot end sampling for dimensional checks.

Hot-end ware rejection is an automatic process to ensure quality of the bottles after bottle swabbing. Next, the bottles are put into an annealing chamber, where they are gradually heated and cooled to de-stress.

The bottles then pass through a series of automatic and camera inspection checks by equipment like M, M-Cal, Veritas and VISIGLAS. These machines check for body defects, neck finish, bubbles, foreign matter etc.

The bottles are finally automatically shrink-wrapped, and a sample of the packed bottles is put through a QA process to check for defects.

The container used for transport is fumigated and also checked for cleanliness and hygiene prior to stuffing.

Wide sales and distribution spread

Our sales and distribution presence in most major markets across the globe. Our significant marketing presence in Europe, USA and Caribbean enables us to build more intimate relationships with customers, and respond to their needs quickly and efficiently.

Significant cost advantages

Though the manufacturing of glass itself is highly automated, critical functions such as quality control need large teams of skilled professionals. Not surprisingly, the total cost of production in China, where manpower is among the cheapest in the world, is less than half of that in France and almost half of that in the US. With manufacturing facilities in North China, Unipack Glass is able to produce glass at significantly lower costs than its competitors in other parts of the world and deliver a sustainable cost advantage to customers.

Decoration services and accessories

Equipped with 4 American STRUTZ3 high-speed printers, 2 Netherlands ROSARIO3 printer, 1 Italian automatic RB-4/6 six-color printer and 6 automatic packaging lines, enable us to make the high quality decoration of the bottles. At the same time we also have lines as decal, frosting, gold plating that can meet the specific requirements of our customers needs.

Our partners include closures, labels as well as packaging machinery manufacturer, allow us to deliver completely customized packaging.

As one of the leading glass manufacturer in North China, we offer one-stop- shop packaging solutions, include full bottle design capabilities, in-house mould design, CNC machines for mould manufacturing, high quality glass manufacturing and dedicated ancillaries for decoration and accessories like caps, cartons and labels

Unipack Glass offers several competitive advantages over other suppliers include:

Strong manufacturing capacity and high standard quality control

With an installed capacity of 2, 280 tonnes per day, makes us able to produce glass bottles and containers in flint, super flint, green, amber color.

At Unipack glass, quality is of paramount importance.

First happens at the IS machine, immediately after the bottle is formed. Here, the line operator, with the quality control checker, does hot end sampling for dimensional checks.

Hot-end ware rejection is an automatic process to ensure quality of the bottles after bottle swabbing. Next, the bottles are put into an annealing chamber, where they are gradually heated and cooled to de-stress.

The bottles then pass through a series of automatic and camera inspection checks by equipment like M, M-Cal, Veritas and VISIGLAS. These machines check for body defects, neck finish, bubbles, foreign matter etc.

The bottles are finally automatically shrink-wrapped, and a sample of the packed bottles is put through a QA process to check for defects.

The container used for transport is fumigated and also checked for cleanliness and hygiene prior to stuffing.

Wide sales and distribution spread

Our sales and distribution presence in most major markets across the globe. Our significant marketing presence in Europe, USA and Caribbean enables us to build more intimate relationships with customers, and respond to their needs quickly and efficiently.

Significant cost advantages

Though the manufacturing of glass itself is highly automated, critical functions such as quality control need large teams of skilled professionals. Not surprisingly, the total cost of production in China, where manpower is among the cheapest in the world, is less than half of that in France and almost half of that in the US. With manufacturing facilities in North China, Unipack Glass is able to produce glass at significantly lower costs than its competitors in other parts of the world and deliver a sustainable cost advantage to customers.

Decoration services and accessories

Equipped with 4 American STRUTZ3 high-speed printers, 2 Netherlands ROSARIO3 printer, 1 Italian automatic RB-4/6 six-color printer and 6 automatic packaging lines, enable us to make the high quality decoration of the bottles. At the same time we also have lines as decal, frosting, gold plating that can meet the specific requirements of our customers needs.

Our partners include closures, labels as well as packaging machinery manufacturer, allow us to deliver completely customized packaging.

More >