Home LED Light Products Glass Clamps, Glass Clips, Glass Fixtures, Shower Door Glass Clamps

Glass Clamps, Glass Clips, Glass Fixtures, Shower Door Glass Clamps

| Price: | US $ 8/Piece |

|---|---|

| Min Order: | 200/Piece |

| Pay Type: | L/C,T/T |

| Prod Model: | DH-D043 |

|---|---|

| Function: | Connecting Glass and Bracing Bar |

| Surface: | Mirror Finish |

| Market: | Middle and High |

| Materials: | Fully Casting 304 Stainless Steel |

| For Glass: | 6-10mm |

| Material: | Stainless Steel |

| Type: | Glass Clamps |

| Color: | Highly Polished Silver |

Product Description

Adavantages1. Shower door clamps with strong structure.

2. 304 stainless steel casting raw materias, endurable

3. Passed 30,000 cycles life test.

4. Highly polished mirror finish.

5. With clean one-piece cover

6. For high and middle market

7. Classic and beautiful design

8. No need to drill holes on glass.

| Code | For tubes | Color | For glass | Net weight |

| DH-D043 | 25*25 square | highly polished silver | 6-10mm | 0.38 |

Company advantages

1. Professional not only on shower door hinges but also on shower doors.

2. Easy to understand your needs. With Rich experiences on shower dooor hinges and shower rooms/shower doors export. Ms. Mary had ever worked in Rosery shower door factory for 11 years as export mananger. She has rich experiences on shower doors design and technical request. She will understand your needs well.

3.Experienced engineer and strick QA request. Our engineer counselor ever studied in Japan who has strict request on hinges design and manufacturing. So our shower door hinges never drop and with high quality.

4. It is ok to export from any port of China.

5. We would like to do LCL load service for you for free.

Company profile

Donghao Hardware built in 2009. We are the first company in China who professionally design, manufacture and supply the whole set shower room components and solutions. We have engineers help you to design and find the appropriate configuration of your shower rooms. Except whole set shower room solutions we also manufacture and supply shower room components as single parts, which includes stainless steel profiles, stainless steel hinges, stainless steel clamps, stainless steel pivots and stainless steel handles.

"Quality first, Customers focus" is our managements aim. We perform ISO 9001 quality management strictly during every process and our quality management focuses on the aim of satisfying customers from the designing of products, which ensures us to supply customer high quality products rapidly.

ODM is our best advantage. We have experienced engineers on ODM and bespoken components and shower rooms. So we can design and make products belong to you and supply you solution for both components and shower rooms. We would like to work with you to create your own products and your own glory!

QA process

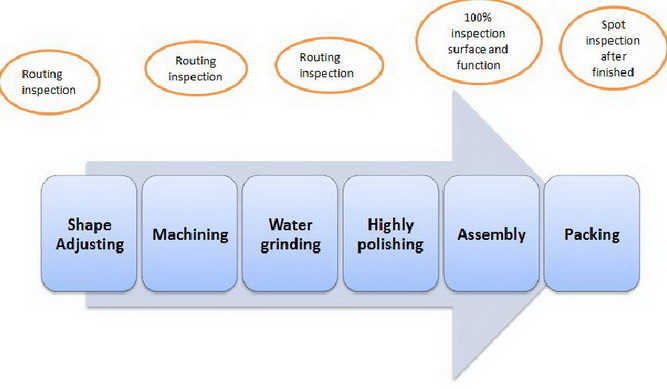

Incoming materials QC-- Process inspection--Finished products inspection

Process flow

First step is to adjust the shape of the raw mateials to maket is square. Then start machining include drilling, tapping and milling. Then water grinding and then highly polishing. After polishing, we will do 100% inspection on surface to ensure the surface is clean mirror finish. Then start assembly. During assembly we will also do 100% inspection to check the basic function. The last step is to do packing. All the products will be packed in white boxes and then put in a brown cartons.

Quality control process

Factory

Workshop

stainless steel sheet folding to shape workshop shower door hinges, shower door clamps,

mainly making shower door profiles wall brackets workshop

Assembly line

Company profile

Our founder of Zhongshan Donghao Hardware Company and his wife both came from the famous shower door factory ROSERY in China. The founder Mr. Liang is the QA manager in Rosery. And Mary Hao is the export manager in Rosery. She had worked as an export manager in Rosery for 11 years. During these years, she help Rosery find many big customers in the world. So we have strict quality control process and very rich export experience.

We are a company that manufacture not only shower doors but also shower door components include shower door hinges, shower door profiles and shower door bracing bar, handles etc. But all of our shower door components include frames are made of 304 stainless steel which include Ni more than 8.

We sell products in a few ways:

Shower doors

Shower door components separately

Shower door components in sets

We supply OEM and ODM service both on shower doors and shower door components. And we also supply bespoken shower doors or shower door components design solutions. Our shower doors meet CE EN14428+ standard, and all of our hinges passed 30, 000 cycles life test. With our rich experiences on shower doors and shower door hinges we are sure we could you best price performance products.

The workshops we have: Shower rooms workshop, shower rooms profiles workshop, shower door hinges and other hardware workshop.

We have 5 pieces digital equipment for shower door profiles folding and hinge milling machining process. This equipment helps us to produce accurate and good quality products for you.

"Customer first, quality is life" is our working slogan. Hope you become our customers and hope to cooperate with you!

Our founder of Zhongshan Donghao Hardware Company and his wife both came from the famous shower door factory ROSERY in China. The founder Mr. Liang is the QA manager in Rosery. And Mary Hao is the export manager in Rosery. She had worked as an export manager in Rosery for 11 years. During these years, she help Rosery find many big customers in the world. So we have strict quality control process and very rich export experience.

We are a company that manufacture not only shower doors but also shower door components include shower door hinges, shower door profiles and shower door bracing bar, handles etc. But all of our shower door components include frames are made of 304 stainless steel which include Ni more than 8.

We sell products in a few ways:

Shower doors

Shower door components separately

Shower door components in sets

We supply OEM and ODM service both on shower doors and shower door components. And we also supply bespoken shower doors or shower door components design solutions. Our shower doors meet CE EN14428+ standard, and all of our hinges passed 30, 000 cycles life test. With our rich experiences on shower doors and shower door hinges we are sure we could you best price performance products.

The workshops we have: Shower rooms workshop, shower rooms profiles workshop, shower door hinges and other hardware workshop.

We have 5 pieces digital equipment for shower door profiles folding and hinge milling machining process. This equipment helps us to produce accurate and good quality products for you.

"Customer first, quality is life" is our working slogan. Hope you become our customers and hope to cooperate with you!