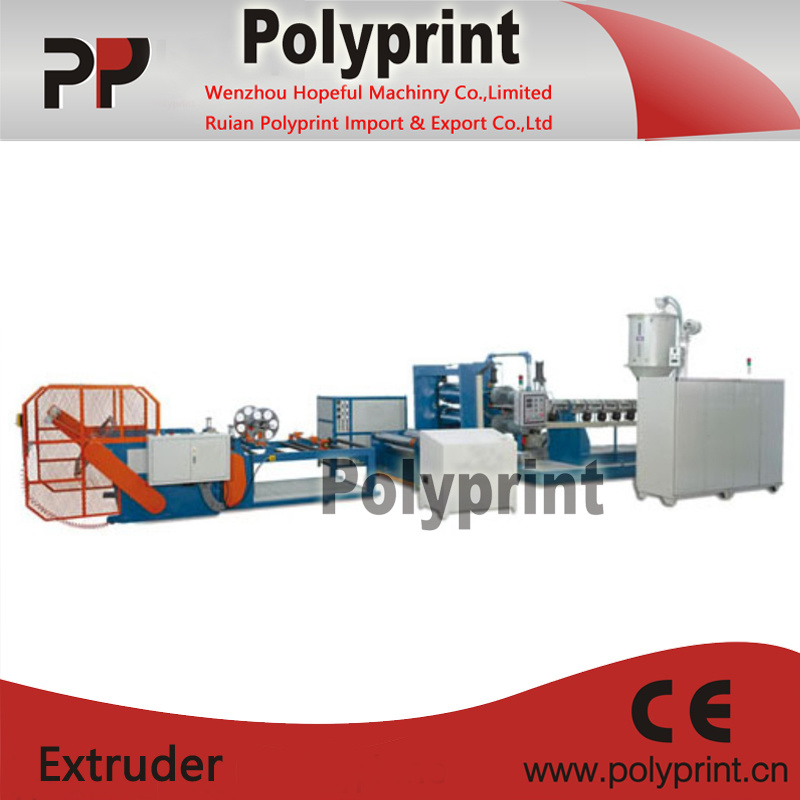

Home LED Light Products in-Line Plastic Extrusion & Cup Thermoforming Production Line (PPSJ)

in-Line Plastic Extrusion & Cup Thermoforming Production Line (PPSJ)

| Price: | US $ 33000-160000/Set |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,D/P |

| Prod Model: | PPSJ |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Fully Automatic: | in-Line |

Product Description

APPLICATION:It is suitable for PP, PS, PLA, PET, PVC etc material. It mainly produce the containers such as water cups, drinking cups, milk cups, bowls etc.

FEATURE:

Rapid mould changing device

Buffer design is adopted for the width of chain holder thus eliminating chain binding condition resulting from insufficient heating of sheet.

Up and down ceramic heater are adopted for heating with several sets of SSR and PID temperature control

Automatic stacker system

PLC and humanized color touch screen control operation interface.

Mould automatic memory system.

| In-line Sheet Extrusion Line | ||

| 1 | Suitable Material | PP, HIPS |

| 2 | Sheet Thickness | 0.4-2.0 mm |

| 3 | Max. Sheet Width | 750 mm |

| 4 | Max. Output (Raw Material) | 400 kgs/h (Sheet Thickness > 0. 8 mm) |

| 5 | Power (Industry Use) | 3Phx380V/50Hz |

| 6 | Water Temperature | 20- 25° |

| 7 | Water Pressure | 2-4 bar |

| 8 | Air Source | 6-8 bar, Air Consumption <50 L/min |

| 9 | Total Install Power | 250 kw |

| In-line Cup Thermoforming Machine | ||

| 1 | Max. Forming Area | 685×320mm |

| 2 | Max. Forming Depth | 130mm |

| 3 | Max. Clamping Force | 300KN |

| 4 | Dry Cycles Speed | 42 Cycles/min |

| 5 | Sheet Width Range | 550-720mm |

| 6 | Sheet Thickness | 0.35-2.0mm |

| 7 | Max. Roller Diameter | Φ1000mm |

| 8 | Air Pressure | 0.7-0.85mpa |

| 9 | Water Consumption | 50 L/min |

| 10 | Air Consumption | 3000 L/min |

| 11 | Heating Power | 130kw |

| 12 | Machine Weight | 11500kg |

| 13 | Dimension | 12500×3650×3550mm |

| 14 | Power (3 Phase 3 Wire) | 3×380V+NP+PE.50HZ |

Ruian Polyprint Machinery Co., Limited specializes in manufacturing plastic PP and PS extruder machine and thermoforming machine. Such as plastic sheet extrusion line, thermoforming machine, and on-line cup making machine, cup lid forming machine, cup lip curling machine, cup automatic packing machine with a batch of semi-senior and senior technical experts, our company has obtained ISO9001 quality system certificate which combined design, development, manufacture, installation and service in to system.

Our products are mainly exported to America, Europe, southeast Asia and southwest Africa. Most of our products are accepted and favored by our clients from all over the world. With the principle of scientific management, our company actively carries out ISO9001 quality management system and implements this standard strictly.

The slogan that best epitomizes our approach to quality is: Service must run ahead of time, the customer is our priority, take technology as our lead, and production must be carried out meticulously and with care. Based on these principles our company has been successfully improving the quality of its products, talking active measures and making reasonable use of its resources.

What we are now striving for is to transform our company into the No 1 packaging manufacturer by exploiting our qualities and promoting ourselves publicly, building ourselves a better profile within the industry. We are looking for serious partners to join us in fruitful commercial ventures. Contact us today to find out more.

Our products are mainly exported to America, Europe, southeast Asia and southwest Africa. Most of our products are accepted and favored by our clients from all over the world. With the principle of scientific management, our company actively carries out ISO9001 quality management system and implements this standard strictly.

The slogan that best epitomizes our approach to quality is: Service must run ahead of time, the customer is our priority, take technology as our lead, and production must be carried out meticulously and with care. Based on these principles our company has been successfully improving the quality of its products, talking active measures and making reasonable use of its resources.

What we are now striving for is to transform our company into the No 1 packaging manufacturer by exploiting our qualities and promoting ourselves publicly, building ourselves a better profile within the industry. We are looking for serious partners to join us in fruitful commercial ventures. Contact us today to find out more.