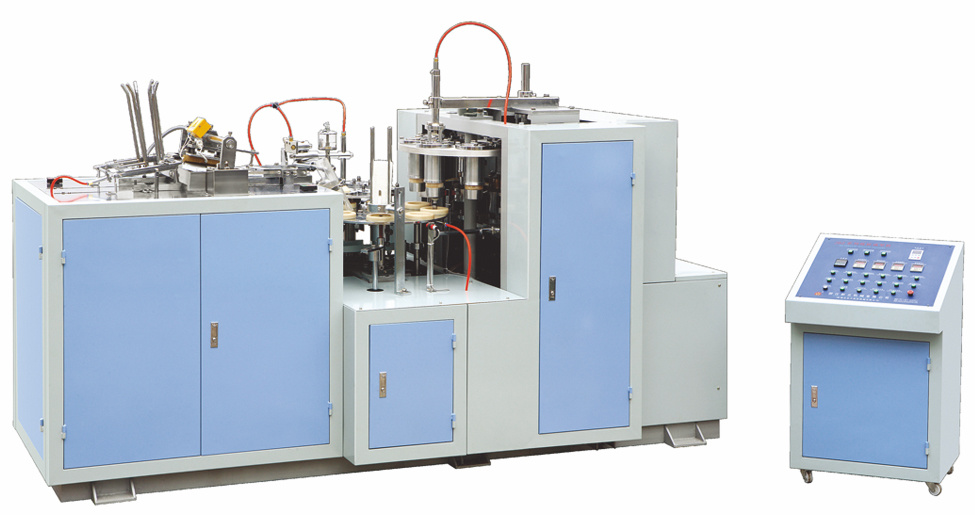

Home LED Light Products Paper Cup/Bowl/Box Forming/Making Machine (JBZ-A)

Paper Cup/Bowl/Box Forming/Making Machine (JBZ-A)

| Price: | US $ 11000-14000set |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1set |

| Pay Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Prod Model: | JBZ-A |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Cup Size: | 4,6,8,9,12,16,22 |

| Capacity: | 80-100PCS/Min |

| Speed: | 40-60pcs/min |

| Required Paper: | Single Side PE Coated Paper |

| Certification: | CE |

| Condition: | New |

| Applicable Objects: | Food,Beverange,Yogurt |

| Cup Size(',Ounce): | 4-22oz |

Product Description

JBZ-A12 paper cup forming machine is a multistation automatic machine producing single-sided PE coated drink cups, ice cream cups or conical vessels of other food through continuous process of automatic paper feed, medium welding tube forming, cup rabbet lubrication, body paper rush, bottom pressing, heating, bottom knurling, upper mouth hemming, binding, unloading and finished product stacking.

Main Characteristics:

1. Precise box type indexing cam structure, the parts all adopt standard production, have high generality and good exchange performance, and facilitate equipment maintenance.

2. The paper holder is provided with paper feeding detection function, so that it will alarm automatically when the paper is less than a certain amount. (optional according to the demand of the customer

3. The heat seal barrel forming part is provided with non-cup-barrel detection, alarming and sopping functions, which enhance the automation degree of the machine. (optional according to the demand of the customer

4. The bottom-punching part is changed into mechanical probe type detection which ensures the detection precision and the pass rate of finished products

5. The machine adopts high-position stopping device, so that the machine always stops at the highest point, the mold and the heating furnace are fundamentally separated and the paper cup is prevented from being burned

6. The large vertical shaft of the machine adopts oil tank lubricating, which ensures that the vertical shaft is soaked in the lubricating oil and is not damaged after long-time running.

7. The company has improved the rolling part, the bottom punching part, the heating part, the rolling wheel and paper cutting, being capable of producing thick paper which is more than 300g/, and is free of water seepage and water leakage.

Technical Parameter:

| Model | JBZ-A04 | JBZ-A12 | JBZ-A16 | JBZ-A22 |

| Specification of paper cup | 2oz,4oz,4.5oz,6.5oz | 6oz,8oz,9oz,12oz | 8oz,9oz,12oz,16oz | 8oz,9oz,12oz,16oz |

| Paper material | Single side PE coated paper | |||

| Outer diameter of cup rabbet | 50-80 | 50-95 | 50-95 | 50-95 |

| Outer diameter of cup bottom | 35-70 | 35-70 | 35-70 | 35-70 |

| Cup height | 30-60 | 50-120 | 80-150 | 100-175 |

| Bottom depth | ≤10 | ≤10 | ≤10 | ≤12 |

| Conicity | 4-6o | 2-8o | 2-8o | 2-8o |

| Capacity | 40-50pcs/min | 35-45pcs/min | 35-40pcs/min | |

| Power supply | 380V 50Hz | |||

| Total power | 5KW | 6KW | ||

| Weight | 1600Kg | 1900Kg | ||

| Packing size(L*W*H) | 2800×1350×1760mm 730×600×1100mm | 3000×1350×1900mm 730×600×1100mm | 3300×1450×2000mm 730×600×1100mm | |

Sample:

Packaging & Shipping:

Our Service:

1. Warranty

1 year limited warranty after installation.If the spare parts is broken in the warranty

period , we will send a free replacement parts to you .

2. Installation and Training

We can send 1-2 engineers to buyers factory to install and set up the machines and

training, but all the charges for the engineers should be paid by buyer.

3. Quotation

The quotation is available in 60 days

Wenzhou Changs Machinery Co., Ltd is one of the first company specialized in manufacturing printing machines, packing machines, plastic machine and paper converting machines, has owned export and import license since 2004.

To consider our full service convenience, we have set up service office and showing room at DRAGON-MART of Dubai to provide technical service for customers from Middle East and Africa in 2006, and also we have established technical support offices in Mexco, Egpty and Singapore, our service has satisfied with all of our customers. We enjoy sound reputation in oversea's market and domestic.

To serve buyers the best machine and ensure our machines are with reliability quality, our factory employed skilled engineers and using advanced technology equipment, the raw material and components are carefully selected. Meanwhile, we have built closely cooperative relationship with domestic colleges, universities and R&D institutes. Further on we have established a solid relationship with reliable equipment suppliers and our service team are got rich experience in the industry.

Changs International is located in Wenzhou which is a coast city, it is near to Shanghai or Ningbo port. The convenient transportation reduces transport cost and shortened machine's delivery time aswell.

Being persistent, honest and trustworthy is our Changs International's beliefs, we are building service brand to fully meet the reasonable requirement of customers. Get in touch with www. Changsinter. COM today to find your needful here.

To consider our full service convenience, we have set up service office and showing room at DRAGON-MART of Dubai to provide technical service for customers from Middle East and Africa in 2006, and also we have established technical support offices in Mexco, Egpty and Singapore, our service has satisfied with all of our customers. We enjoy sound reputation in oversea's market and domestic.

To serve buyers the best machine and ensure our machines are with reliability quality, our factory employed skilled engineers and using advanced technology equipment, the raw material and components are carefully selected. Meanwhile, we have built closely cooperative relationship with domestic colleges, universities and R&D institutes. Further on we have established a solid relationship with reliable equipment suppliers and our service team are got rich experience in the industry.

Changs International is located in Wenzhou which is a coast city, it is near to Shanghai or Ningbo port. The convenient transportation reduces transport cost and shortened machine's delivery time aswell.

Being persistent, honest and trustworthy is our Changs International's beliefs, we are building service brand to fully meet the reasonable requirement of customers. Get in touch with www. Changsinter. COM today to find your needful here.