Home LED Light Products Plastic Save Space Shoes Rack

Plastic Save Space Shoes Rack

| Price: | US $ 0.01/Piece |

|---|---|

| Trade Terms: | FOB |

| Min Order: | 100/Piece |

| Pay Type: | L/C,T/T |

| Prod Model: | Plastic Save Space Shoes Rack |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Shoes Rack: | Plastic Save Space Shoes Rack |

| Injection Molding: | Moding |

Product Description

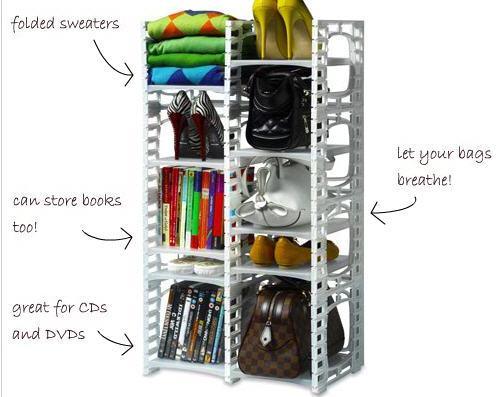

Plastic save space shoes rack, save space shoes rack, plastic shoes rack, shoes rackAdvantages

With the experience in cooperating with famouse branded company, such as Lipton, KFC, our company is recognized as a reliable supplier who always offers reasonable price, guaranteed quality, sincerely service.

Factory directly sell, with strong ability to develop a customized sample according to clients' requirment, such as size, shape, color, material, Logo, packing, etc. And we use environmental-friendly material, no toxin.

We are confident in our ability to gurantee the best quality and believe our products will bring a complete satisfaction to the end users. We welcome your valuable inquiry and we will be happy to reply you immediately. Please feel free contact us.

Innovation napkin bins

1. Material: Plastic

2. Usage: As a tool for stock

3. Packing: According to customers request

4. Size: It can follow customers requested size

5. Shape: Geometry, customers design shape are welcomed

6. MOQ: 500PCS

7. Production lead time: 15days after receiving deposit

8. Supply ability: 10000 pieces/month

9. Sample lead time: 5 days

| Packaging Detail: | Carton |

| Delivery Detail | 5 ~ 10 days |

| Material | ABS, AS, PPS, PP, POM, PC, PA, PMMA, PS, HDPE, TPE, TPU, TPR | |

| Design | As drawing or sample | |

| Lead Time | 5 - 10 days | |

| Packing | Outer packing: Carton Inner | Inner packing: plastic bag |

| Place of Origin | Guangdong, China | |

| Advantage | Advanced equipment and excellent R& D Team | |

| Highly skilled manufacturing process | ||

| A broad variety of ODM& OEM product range | ||

| Strict quality Control System | ||

Yuyao Xianghao Mold Technology Company Limited is founded in 2001, is an integrated manufacturing company, specializing in development, design, manufacture of rapid prototype, plastic injection mould, Die-Casting Die, moulding products, as well as finished products assembly which applicantion for Household appliances, kitchenware, transportation tool, digital & telecommunication products, toys, custom products, auto parts, etc. The company is located in YuYao Mold City, zhejiang province of China which is close to Shanghai& HangZhou airport, it is very convenient to transportation.

In the past, we updated ourselves to the International Standard and granted an ISO 9001-2000 certificate. Sticking to "Customer First, Science & Technology First ". Droow-Mold adopts the TQM system focused on customer's projects constantly improve the technical process so as to strictly supervise and control the whole process from the initial design to manufacture which has further ensured the high quality products.

Thanks to the excellent teamwork spirit of darrow Mold staff and great support of customer, the company annually turns out 600-900 standard top quality set of moulds. About 70% of moulds are exported to Europe, USA, Australia, Russia and other countries which mainly used in Auto parts, Home appliances, Household products, Computer hardware, Medical Enclosures, Communication parts, Consumer electronics, Office supplies etc. We have built straight or indirect business relationship with many famous companies like Honda, Volvo, Peugeot Audi, Renault, VALEO, HP, PHILIPS, CASIO, RICOH, KINPO, ARRK and TANITA etc.

Darrow Mold has a group of experienced designer, engineer and technician. High quality standard, competitive price, on time delivery, and responsible after-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

We believe in darrow-Mold will to be the top in the word by the advanced management concept and experienced workmanship, & with the concept of "quality and technology is the soul of products", we sincerely hope to create prosperous business hand in hand with global customers.

In the past, we updated ourselves to the International Standard and granted an ISO 9001-2000 certificate. Sticking to "Customer First, Science & Technology First ". Droow-Mold adopts the TQM system focused on customer's projects constantly improve the technical process so as to strictly supervise and control the whole process from the initial design to manufacture which has further ensured the high quality products.

Thanks to the excellent teamwork spirit of darrow Mold staff and great support of customer, the company annually turns out 600-900 standard top quality set of moulds. About 70% of moulds are exported to Europe, USA, Australia, Russia and other countries which mainly used in Auto parts, Home appliances, Household products, Computer hardware, Medical Enclosures, Communication parts, Consumer electronics, Office supplies etc. We have built straight or indirect business relationship with many famous companies like Honda, Volvo, Peugeot Audi, Renault, VALEO, HP, PHILIPS, CASIO, RICOH, KINPO, ARRK and TANITA etc.

Darrow Mold has a group of experienced designer, engineer and technician. High quality standard, competitive price, on time delivery, and responsible after-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

We believe in darrow-Mold will to be the top in the word by the advanced management concept and experienced workmanship, & with the concept of "quality and technology is the soul of products", we sincerely hope to create prosperous business hand in hand with global customers.