Home LED Light Products SUS316L Stainless Steel MIM Metal Parts for Mobile Phone Decoration Parts

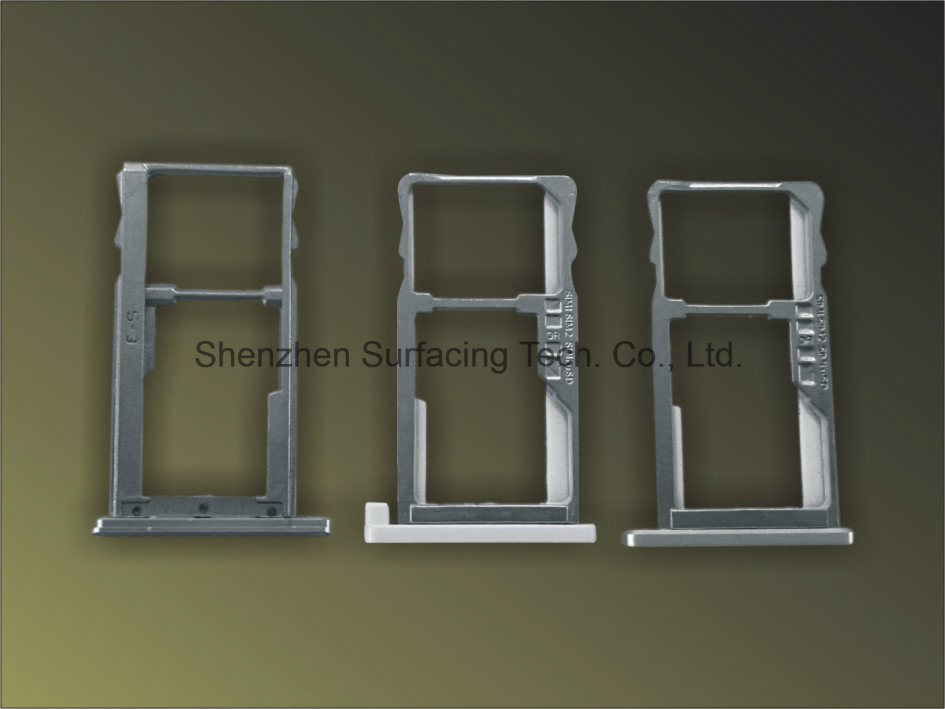

SUS316L Stainless Steel MIM Metal Parts for Mobile Phone Decoration Parts

| Price: | US $ 0.03-0.06/Piece |

|---|---|

| Min Order: | 100/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

| Prod Model: | SFS-ELE |

|---|---|

| Size: | Customized |

| Application-: | Cellphone Camera Cover |

| Specification-1: | Product Weight : 0.001 Kg |

| Compatible Cellphone: | iPhone /Samsung/ Huawei /Mi |

| Deep Processing: | Polished, Chamfered, Sandblasted |

| Compatible Brand: | All Brand |

| Accessories: | SIM Cards |

| Parts: | SIM Card Holder Slot |

Product Description

SUS316L Stainless Steel MIM Metal Parts for Mobile Phone Decoration Parts

Product Name | SUS316L Stainless Steel MIM Metal Parts for Mobile Phone Decoration Parts |

Material | SUS316L |

Compatible Cellphone | iPhone /Samsung/ Huawei /MI |

Application | Cellphone Camera Cover |

Deep processing | Polished, chamfered, sandblasted |

Brief Brochure of SFS MIM :

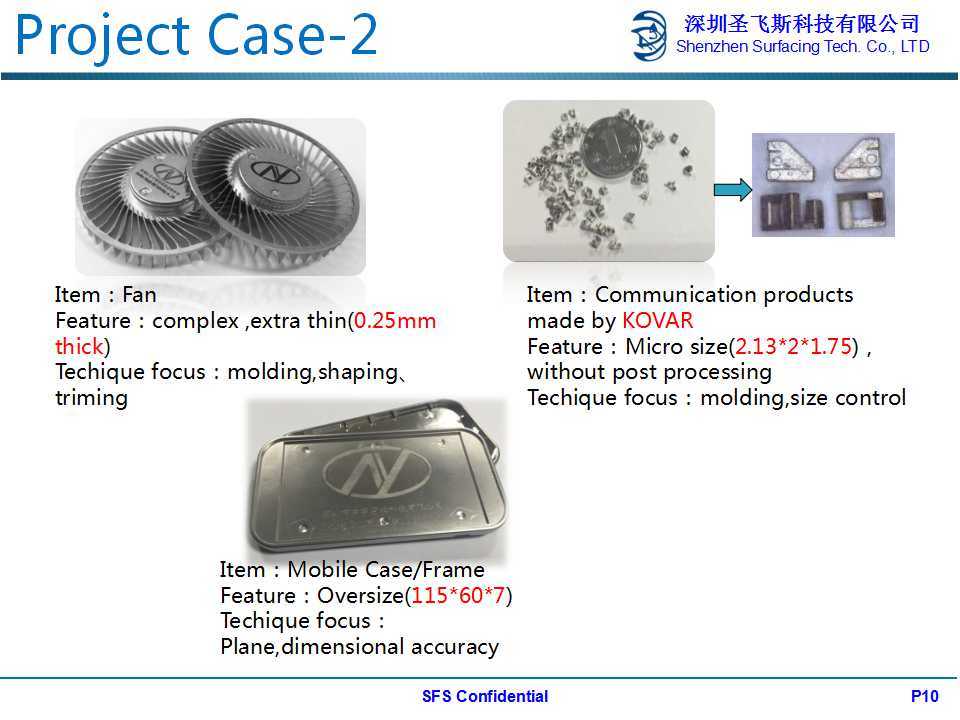

SFS metal Products experienced at producing MIM part for today's consumer electronic components. We specialize in metal injection molding of soft magnetic alloys, stainless steel, and a range of other ferrous metals. The MIM process is ideal for producing small, complex electrical components with excellent mechanical properties.

Computer and Electronic Product SolutionsFSF experience include: Fiber Optic Connectors, Filter Components, Heat Sinks, Microwave Equipment, Mobile Phones, Solenoids, Micro-Switches, Standoffs, Connectors, Distribution Frames, Switching Components

Our MIM manufacturing experts create precise parts fast. SFS utilizes the BASF/Catamold production system, and has over 25,000 feet of state-of-the-art capacity. And with complete "Part Program Management" SFS Metal Products has extensive industry expertise. This includes complete process engineering, designing and implementing automation, quality assurance, assembly, packaging and product fulfillment and distribution.

Send us your CAD File or Drawings and we'll give you an appraisal of the viability of MIM molding for your new or existing project.

Why Chose SFS MIM:

- Mass production of complex shaped metal parts.

- Quantities from a few thousands to millions.

- Can bring significant cost reduction v/s machining.

Order Process :

Who we are:

We are leading Metal Injection Molding (MIM) and physic vapor deposition coating (PVD) fabricator and manufacturer in Shenzhen, China. Advanced technology and equipment, skillful work force, experienced technical and management team, stable material supply, and good quality control system insure we produce high precise and complex metal injection molded parts for extensive applications

Where we are:

Shenzhen Surfacing Technology Co., Ltd Located in Fuyong, Shenzhen, China

What we can do for you:

Our Metal injection molding plant started in 2005. The annual capacity is 70 tons parts from our continue line and batch furnaces.

We use high efficiency debinding technology and very stable feedstock from BASF to make 316L, pH 17-4, iron base, copper base, and other kinds of precious metal parts, like mobile phone keys, windows and etcs, tools, machine parts, cable connectors, belts, electronic devices parts, jewelry and etc.

What material can be used for Metal injection Molding:

Ferrous alloys:

Steels

Stainless steels

Tool steels

Iron-nickel magnetic alloys

Specialty ferrous alloys (Invar and Kovar)

Tungsten alloys:

Tungsten heavy alloys

Tungsten-copper

Hard materials:

Cobalt-chromium

Cemented carbides (WC-Co)

Cermets (Fe-TiC)

Special materials:

Aluminum

Precious metals

Titanium alloys

Nickel

Nickel-base super alloys

Molybdenum

Molybdenum-copper

Particulate composites

Other specific materials:

Stainless steel:

316L Stainless steel

17-4pH stainless steel

420 stainless steel

440C stainless steel

430/303/304

Low alloy steel:

Fe-2Ni low alloy steel

Fe-8Ni

What is our product range:

1. Auto components: Air bags, auto locks, safety belts, jacking systems of auto doors, small gears, auto AC systems, racks of braking systems and sensors of fuel systems

2. Military components: Guns, bullets and fusses

3. Computer and IT industry components: Typewriters, magnetic cores, firing pins, axle pins, drive parts and porcelain plugs of optical communication

4. Tool components: Drill bits, tool bits, nozzles, thread milling cutters, pneumatic tools, and fishing gears

5. Home appliances: Watch cases, watch chains, electric toothbrushes, scissors, golf heads, jewelry links, cutting tools and tool bits

6. Medical instrument components: Orthodontic device, shears and tweezers

7. Electric components: Mini motors and sensors

8. Machinery components: Textile machines, beading machines and office machines

Our Business Partner:

The world's largest contract electronics manufacturer-Foxconn

China biggest phone maker-Huawei

We are leading Metal Injection Molding (MIM) and physic vapor deposition coating (PVD) fabricator and manufacturer in Shenzhen, China. Advanced technology and equipment, skillful work force, experienced technical and management team, stable material supply, and good quality control system insure we produce high precise and complex metal injection molded parts for extensive applications

Where we are:

Shenzhen Surfacing Technology Co., Ltd Located in Fuyong, Shenzhen, China

What we can do for you:

Our Metal injection molding plant started in 2005. The annual capacity is 70 tons parts from our continue line and batch furnaces.

We use high efficiency debinding technology and very stable feedstock from BASF to make 316L, pH 17-4, iron base, copper base, and other kinds of precious metal parts, like mobile phone keys, windows and etcs, tools, machine parts, cable connectors, belts, electronic devices parts, jewelry and etc.

What material can be used for Metal injection Molding:

Ferrous alloys:

Steels

Stainless steels

Tool steels

Iron-nickel magnetic alloys

Specialty ferrous alloys (Invar and Kovar)

Tungsten alloys:

Tungsten heavy alloys

Tungsten-copper

Hard materials:

Cobalt-chromium

Cemented carbides (WC-Co)

Cermets (Fe-TiC)

Special materials:

Aluminum

Precious metals

Titanium alloys

Nickel

Nickel-base super alloys

Molybdenum

Molybdenum-copper

Particulate composites

Other specific materials:

Stainless steel:

316L Stainless steel

17-4pH stainless steel

420 stainless steel

440C stainless steel

430/303/304

Low alloy steel:

Fe-2Ni low alloy steel

Fe-8Ni

What is our product range:

1. Auto components: Air bags, auto locks, safety belts, jacking systems of auto doors, small gears, auto AC systems, racks of braking systems and sensors of fuel systems

2. Military components: Guns, bullets and fusses

3. Computer and IT industry components: Typewriters, magnetic cores, firing pins, axle pins, drive parts and porcelain plugs of optical communication

4. Tool components: Drill bits, tool bits, nozzles, thread milling cutters, pneumatic tools, and fishing gears

5. Home appliances: Watch cases, watch chains, electric toothbrushes, scissors, golf heads, jewelry links, cutting tools and tool bits

6. Medical instrument components: Orthodontic device, shears and tweezers

7. Electric components: Mini motors and sensors

8. Machinery components: Textile machines, beading machines and office machines

Our Business Partner:

The world's largest contract electronics manufacturer-Foxconn

China biggest phone maker-Huawei

More >