Home LED Light Products TM-Xy150 Tabletop Manual 1 Color Tempo Printer for Pens

TM-Xy150 Tabletop Manual 1 Color Tempo Printer for Pens

| Price: | US $ 800/Set |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

| Prod Model: | TM-XY150 |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Pad Printing Machine Name: | TM-Xy150 Manual 70mm Ink Cup Pad Printer |

| Ink Cup Size: | Dim 70 mm |

| Plate Size: | L 214 * W 100mm |

| Worktable Size: | L 105 * W 180mm |

| Workpiece Height: | 100 mm |

| Workpiece Length: | 100 mm |

| Power: | 110/220V 60/50Hz |

| Dimensions: | L 356 * W 178 * H 443 mm |

| Printing Area: | L 80 * W 60 mm |

| Weight: | 26 Kgs |

| Transmission Type: | Single-Colour Pad Printer |

| Speed(pcs/hr): | 1100 |

| Usage: | Electronic Products/Plastic Shell/ Hardware/Craft |

Product Description

Basic Info.TM-XY150 Desktop Manual Full Set Single Color Pad Printer

Installation Video:

http://v.youku.com/v_show/id_XNTQ2NzQzMzA0.html

Work Video:

http://v.youku.com/v_show/id_XNTc4MTA2NDEy.html

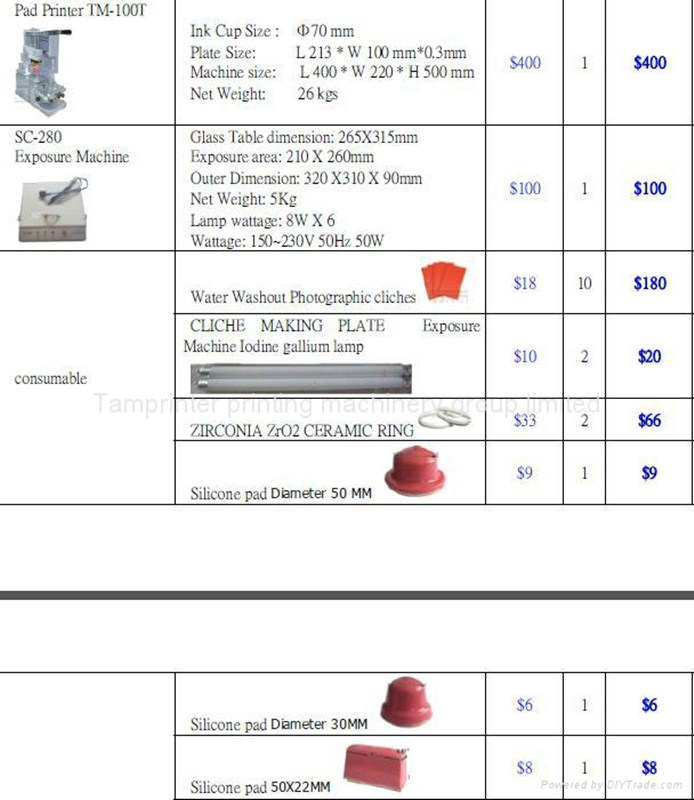

1set TM-100T Manual 70mm Ink Cup Pad Printer

1set SC-280 BSF Mini Exposure Machine

10pcs Water Washout Photographic pad cliches

3pcs Silicone Pad large size

2pcs Pad printing ink scraping ring

2pcs Exposure Machine Iodine gallium lamp

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the printing plate (cliché) via a silicone pad onto a substrate (surface to be printed).

Pad printing is used for printing on otherwise impossible products in many industries including medical, automotive, promotional, apparel, electronics, appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductiv inks, adhesives, dyes and lubricants.

Physical changes within the ink film both on the cliché and on the pad allow it leave the etched image area in favor of adhering to the pad, and to subsequently release from the pad in favor of adhering to the substrate (material being printed).

The unique properties of the silicone pad enable it to pick the image up from a flat plane and transfer it to a variety of surface (i.e. flat, cylindrical, spherical, compound angles, textures, concave surfaces, convex surfaces

Why use pad printing ?

Pad printing is used for printing on various substrates like Plastics, Metals, Glass and Ceramics, Paper and Cardboard, Leather. However, it is primary used in places where the printing area is small and / or the contour or surface of the object is not flat or hard to reach by other printing process.

* Engineering items

* Golf products

* Hangers

* Highlighters

* Key rings

* Letter openers

* Lighters* Mugs

* Paper weights

* Pens

* Pencils

* Rulers

* Sunglasses * Ashtrays

* Bicycle helmets

* Brochure holders

* Business card holders

* Calculators

* Cassettes

* Coasters

* Computer products

* Construction helmets

* Badges

* Telephone boards

* Toys

* Mobile phone holders

Pad printing work includes 2 processes: Plate making Process and Printing Process

1.Manual 70mm Ink Cup Pad Printer TM-100T

Installation Video

http://v.youku.com/v_show/id_XNTQ2NzQzMzA0.html

work video:

http://v.youku.com/v_show/id_XNTc4MTA2NDEy.html

MANUAL PAD PRINTING MACHINE (WITH INK CUP)

Characteristics:

(1) It is the first Printing machine in our Printing Production Category. It has been developed and redesigned over the years to meet our users ever changing needs.

(2) The appearance, technical specifications, and the printing precision have been improved to increase the quality and value for the user.

(3) This machine requires no energy source, it can be easily moved, and offers low cost printing with high precision.

(4)The operation is simple and can be used for printing cosmetic packaging, sporting equipment, electrical and electronic components, and other goods trademark.

Parameter:

| No. of Colors | 1 |

| Ink Cup Size | Φ70 mm |

| Plate Size | L 214 * W 100 mm |

| Worktable Size | L 105 * W 180 mm |

| Workpiece Height | 100 mm |

| Workpiece Length | 100 mm |

| Printing Area | L 80 * W 60 mm |

| Vertical Stroke | 100 mm |

| Horizontal Stroke | 150 mm |

| Up/Down Worktable | 50 mm |

| Machine Dimension | L 356 * W 178 * H 443 mm |

| Package Dimension | L 430 * W 250 * H 480 mm |

| Net Weight | 26 kgs |

| Gross Weight | 28.5 kgs |

Advantages:

1. Manual operating .

2. Easy to change plate.

3. Lower price.

4. Coin aluminium structure.

Basic Configuration:

1. One pad

2. One steel plate

3. One blade.

4. One operation manual

Printing Elements:

1. Pad ink and thinner;

2. Fixture;

3. Pad plate;

4. Rubber pad.

2.SC-280 BSF Mini Exposure Machine

Desktop UV Exposure machine /SC-280 BSF Mini Exposure Machine/small Exposure unite/card exposure machine/ resin plate exposure machine is special desktop style UV exposure unit.

Technical parameter:

| Glass Table dimension | 265X315mm |

| Exposure area | 210 X 260mm |

| Outer Dimension | 320 X310 X 90mm |

| Net Weight | 5Kg |

| Lamp wattage | 8W X 6 |

| Wattage | 150~230V 50Hz 50W |

| Price Terms | EXW Shenzhen, China |

| Packing | CTNS |

| Lead Time | 7 days after payment |

| Standards Certificate | CE |

| Volume | 0.01 |

| Application area | PS plate, BSF plate,resin plate |

| Gross Weight | 13KG |

| Main Parts | cliche UV LAMP |

| Wavelength | 3500 - 4599 angstroms |

| Exposure time | continuously adjustable from 0 to 5.5 minutes |

Application:

CLICH MAKING PAD PLATE MAKING

It is small, compact, stable light source, low voltage can normally start, wavelength very Coincide to ps plate, Exposure in plates with text, image clarity, high resistance to printing and other features. Suitable for printed trademarks, business cards, invitations, table etc.

3.water washable polymer plates

1, made by Japan

Golden resin sheet base Size:

594X420*0.43mm(A2)

20PCS/package

MOQ 1pcs

EXW price: USD63~80/pcs, more order more discount.

If You order

100mm x 250mm 100pcs = A2 8pcs=$70*8=$560

100mm x 100mm. 100pcs= A2 5pcs=$75*5=$375

150mm x 150mm. 3000pcs= $3.375/pcs

2, made by Japan

Golden resin sheet steel bottom Size:

594X420X0.73

Pack of 20, most

MOQ 3 boxes.

$ 850 / box

3, made by Germany

Red steel base resin sheet specifications:

562X610X0.73

Pack of 10.

MOQ 1 box

$ 1,000 / close

Not split

polymer steel cliche water soluble solid photopolymer plate

(one side its steel, other side its polymer), and that cliche its to be used with tampograpy machines, also the cliche its must to be Water Washout,

Supply photographic plate is used for

1, Pad printing machine ,

Only for uv ink ,oily ink.

Not for Water-based ink,alcohol ink.

If need to perforated metal for locate,pls give us drawing.

2, Hot stamping machine,

3, Not for flexo.

4, What size of length, width, thickness ?What brand ,quantity, delivery?

5, Can be divided, Size according to customer requirements.

A. ORIGIN: Japan, brand: Toyobo.

Steel base Photographic plate, pad printer plate,

photopolymer plate, Sensitive resin version ,Flat printing, washable nylon printing plate , Washed with water plate, alcohol wash out plate, printing plate

size: 594X420*0.43mm(A2) 20PCS/package

EXW price: USD63~80/pcs, more order more discount.

Closed cup is available as well as doctor blade with excellent durability because of highly cross-linked photopolymer.

Key advantages

1 Easy processing

Possible to make plates in house due to easy and short processing.

2 Water washable

No necessity of any toxic solvent. Just water!

3 High reproducibility

Allow to print very fine dots and lines. Our recommendation is to use 95%/300lpi screen film.

4 High durability

C. Made in China, brand: Tamprinter.

Resin version, Photopolymer, Water-soluble solid photopolymer plate, Optical resin version, Quality resin plate

| exposure time | 4~8min |

| Washout time | 3~6 min |

| Washout Water Temperature | 40°C~50°C |

| Bake plate Time | 20~40 min |

| Bake plate Temperature | 60°C~80°C |

| Second exposure time | 5~10 min |

| Photosensitive layer height | 0.8~1.3mm |

size: 594X420*0.43mm(A2) 20PCS/package

Can arbitrarily cut,EXW price: Min 5$/pcs

4.Exposure lamp uv lamp

Parameters:

| Item | POWER KW | LAMP (POWER SUPPLY ) V | LAMP POWER A | LENGTH mm | light size mm | UV LAMP mm | mm/jw |

| GG1000 | 1 | 135 | 8.1 | 225 | 125 | 25 | 80 |

| GG1001 | 1 | 135 | 8.1 | 335 | 200 | 25 | 50 |

| GG2000 | 2 | 300 | 7.5 | 400 | 250 | 22.5 | 80 |

| GG3000 | 3 | 700 | 5.0 | 360 | 250 | 25 | 120 |

| GG3001 | 3 | 700 | 5.0 | 620 | 460 | 22.5 | 80 |

| GG4000 | 4 | 500 | 8.8 | 485 | 340 | 25 | 120 |

| GG4001 | 4 | 620 | 7.2 | 700 | 600 | 25 | 80 |

| GG5000 | 5 | 700 | 7.8 | 700 | 600 | 25 | 80 |

| GG5001 | 5 | 750 | 7.5 | 725 | 625 | 22.5 | 80 |

| GG5002 | 5 | 750 | 7.5 | 775 | 625 | 22.5 | 80 |

| GG5003 | 5 | 850 | 6.3 | 778 | 625 | 22.5 | 80 |

| GG5004 | 5 | 850 | 6. 3 | 804 | 653 | 20.5 | 80 |

| GG5600 | 5.6 | 950 | 7. 2 | 826 | 700 | 25 | 80 |

| GG5601 | 5.6 | 950 | 7. 2 | 1020 | 900 | 25 | 50 |

Packing: CTNS

Lead Time: 5DAYS AFTER PAYMENT

Standards Certificate: CE

Application area: UV CURING MACHINE ,UV DRYER, UV OVEN

Using methods and precautions:

1. Must be appropriate choke tube, supporting the use of triggers.

2. Avoid handling the lamp by hand in order to avoid direct contact with the tube surface contamination devitrification.

3. The lamp when working with strong ultraviolet radiation, must be taken to avoid burns to eyes and skin protection

4. Matching the power of the lamp are high, you should pay attention to routine inspection and maintenance.

5. Exposure time not too long, typically 20-120 seconds.

6. Tubes at a fixed point on the head, not in the ignition when the end of the wire suspension force.

Welcome to contact us if you have any question!

Tamprinter printing machinery group limited is one of the most professional special printer supplier of package paper and plastic sheet Field in China. We have supplied OEM service for the domestic counterparts since 2003. OEM products have been achieved CE certification.

Due to business expansion, Shenzhen Tamprinter printing machinery limited International trade department have been separated from the parent company in March 2013.

Key products: Sheet Screen printer, UV curing machine, IR tunnel oven. Ceramic ring

Major market: UK market.

Business scopes:

1. Research, develop, produce and sell: Screen printer, Pre-post printer(UV curing machine, Flame treatment machine, UV exposure clich machine, Coating emulsion machine, Silk mesh tighten machine, Screen stencil drying oven, Silk screen frame exposure machine, Steel pad plate oven, IR oven, IR drying tunnel conveyer ); Pad printer, , Hot stamping machine,

2. Trade and authorize for the patent of the above products, Services about design, testing, maintenance, and technical consulting;

3. Valet Manufacture: Flame treatment gun, screen frame, Screen Stencil, pad, steel plates, film, Drying Racks Trolley and the relative moulds, jigs and parts;

4. Sale by proxy the relative supporting materials: Printing ink, Ink Adjustment tool, Rubber pads Materials, Pad Printing Blade, ink cup and ring, Pad holder, ink roller, Screen Silk, Aluminium Screen Frame, Rubber Squeegee, sensitive emulsion, Emulsion Coating tool, Etching powder, Sensor Switch, Tension meter, Spraying gun, Circuit board, Inkwell, Solenoid Valve, hot stamping foil, High temperature tape, Stamp plate, Silicon rubber roller, Heat transfer paper, High temperature glue, UV lamp, UV lamps Trigger etc;

5. Our engineer can communicate with clients at anytime in English, design development use UG, Proe, Autocad, Mastercam;

6. Import and export business of the above items.

Applications:

It mainly applies to the printing process and pre-postpress of plastic and hardware products. Our equipment is also applicable to other material as glass, ceramic, wood, leather, cloth, etc.

Involved in the industry:

Electronics, toys, gifts, clothing, stationery, cosmetics, washing products, chemicals, food, health product, pharmaceutical and packaging etc.

Advantages:

1. All the electrical components and control system are from Germany and Japan, guarantee the stable quality of the print.

2. Multi-purpose microcomputer operating panel and touch screen operation can easily achieve man-machine dialogue.

3. As high quality steel frame structure and High temperature of the lacquer that bake, so that our printer is light and solid, beautiful and practical.

Our first-class products and considerate services have won more than 80 countries, acceptance in Europe and the United States, Canada, Southeast Asia, the Middle East and other customer, and we enjoyed a high reputation in the market. We cooperate with Omron, Emerson and Ruigao light, which are the world famous enterprises.

The value rules of our company:

Our vision: To become well-known brands in the industry.

Our belief: Excellence, legendary achievements.

Our aim: To sustained profitability, the Foundation Changchun.

Our customer concept: Improve customer satisfaction, and create a win-win situation.

Our product concept: Safety, energy saving, environmental protection, easy to use.

Our opinion on talent: Loyalty, integrity, professional spirit, dedication.

Our style: Leading front among the people enough to be the first rate of people, self-discipline enough to convince the people.

Our criteria: Compliance with commitments, do what we say.

Our motto: Self-discipline to learn, know one line.

Our slogan: Healthy Living, happy work.

To me, the past is black and white, but the future is always color.

Due to business expansion, Shenzhen Tamprinter printing machinery limited International trade department have been separated from the parent company in March 2013.

Key products: Sheet Screen printer, UV curing machine, IR tunnel oven. Ceramic ring

Major market: UK market.

Business scopes:

1. Research, develop, produce and sell: Screen printer, Pre-post printer(UV curing machine, Flame treatment machine, UV exposure clich machine, Coating emulsion machine, Silk mesh tighten machine, Screen stencil drying oven, Silk screen frame exposure machine, Steel pad plate oven, IR oven, IR drying tunnel conveyer ); Pad printer, , Hot stamping machine,

2. Trade and authorize for the patent of the above products, Services about design, testing, maintenance, and technical consulting;

3. Valet Manufacture: Flame treatment gun, screen frame, Screen Stencil, pad, steel plates, film, Drying Racks Trolley and the relative moulds, jigs and parts;

4. Sale by proxy the relative supporting materials: Printing ink, Ink Adjustment tool, Rubber pads Materials, Pad Printing Blade, ink cup and ring, Pad holder, ink roller, Screen Silk, Aluminium Screen Frame, Rubber Squeegee, sensitive emulsion, Emulsion Coating tool, Etching powder, Sensor Switch, Tension meter, Spraying gun, Circuit board, Inkwell, Solenoid Valve, hot stamping foil, High temperature tape, Stamp plate, Silicon rubber roller, Heat transfer paper, High temperature glue, UV lamp, UV lamps Trigger etc;

5. Our engineer can communicate with clients at anytime in English, design development use UG, Proe, Autocad, Mastercam;

6. Import and export business of the above items.

Applications:

It mainly applies to the printing process and pre-postpress of plastic and hardware products. Our equipment is also applicable to other material as glass, ceramic, wood, leather, cloth, etc.

Involved in the industry:

Electronics, toys, gifts, clothing, stationery, cosmetics, washing products, chemicals, food, health product, pharmaceutical and packaging etc.

Advantages:

1. All the electrical components and control system are from Germany and Japan, guarantee the stable quality of the print.

2. Multi-purpose microcomputer operating panel and touch screen operation can easily achieve man-machine dialogue.

3. As high quality steel frame structure and High temperature of the lacquer that bake, so that our printer is light and solid, beautiful and practical.

Our first-class products and considerate services have won more than 80 countries, acceptance in Europe and the United States, Canada, Southeast Asia, the Middle East and other customer, and we enjoyed a high reputation in the market. We cooperate with Omron, Emerson and Ruigao light, which are the world famous enterprises.

The value rules of our company:

Our vision: To become well-known brands in the industry.

Our belief: Excellence, legendary achievements.

Our aim: To sustained profitability, the Foundation Changchun.

Our customer concept: Improve customer satisfaction, and create a win-win situation.

Our product concept: Safety, energy saving, environmental protection, easy to use.

Our opinion on talent: Loyalty, integrity, professional spirit, dedication.

Our style: Leading front among the people enough to be the first rate of people, self-discipline enough to convince the people.

Our criteria: Compliance with commitments, do what we say.

Our motto: Self-discipline to learn, know one line.

Our slogan: Healthy Living, happy work.

To me, the past is black and white, but the future is always color.