Home LED Light Products Useful Plastic Bicycle Cup Holder Injection Mold

Useful Plastic Bicycle Cup Holder Injection Mold

| Price: | US $ 1000/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T,Western Union,Paypal |

| Prod Model: | gv-mold 0001 |

|---|---|

| Shaping Mode: | Injection Mould |

| Process Combination Type: | Compound Die |

| Application: | Home Use |

| Installation: | Fixed |

Product Description

Useful Plastic Bicycle Cup Holder Injection MoldCompany Introduction

Green Vitality Inductry Co., Ltd is a professional injection mold maker extablished in 1993. We have been delicated to the mold making industry for more than 20 years. Green Vitality has accumulated rich experience and build up a strong steady engineering and manufacturing team, which supports us to become a reliable supplier as well as the strategic partner of customers worldside.

We are offering our customer one stop service for plastic part which includes moldflow, part design , tooling design, tooling manufacture, injection molding, secondary operation and part delivery.

Our main business range includes:

| Automotive | Auto interior plastic case, Auto inner parts, Bumper, Door plate, Lamp shell, Instrument panel, auto connectors , Electrical switch; Car gear, Complete sets of motorcycle parts; | |||||||||||||

| Electronic | Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards, USB Connector, USB housing, Mobile phone plastic part, remote control, key-press; | |||||||||||||

| Mechanical | Motor support plastic part, Pump plastic part, mower plastic parts; | |||||||||||||

| Household | Fashion cup, Juice cup, Some small plastic parts; | |||||||||||||

| Home appliance | TV front cover, TV rear cover, Display cover, Air-conditioner or Refrigerators plastic parts, Washing machine part; | |||||||||||||

| Medical | Hollow fiber dialyzer, Deaf-aid parts, Medical instrument body plastic parts, Blood-pressure meter parts, Blood-pressure meter, Stapler. | |||||||||||||

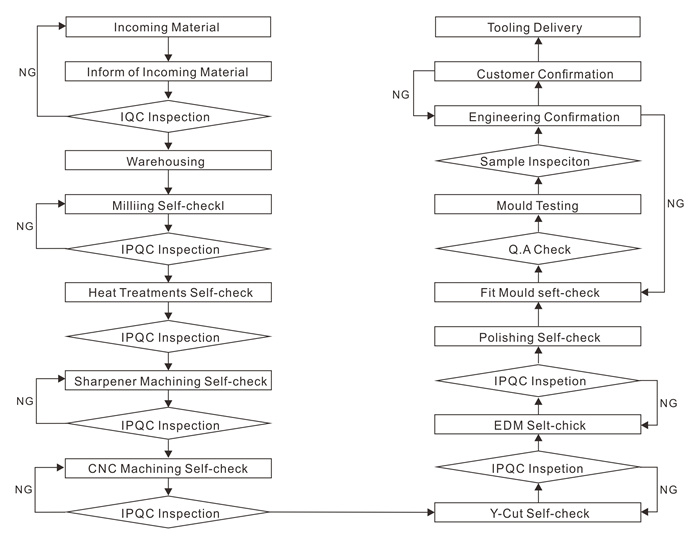

Operation Flow:

Commitment to quality:

- Continually maintaining and improving the effectiveness of our quality management system.

- Periodic review of current quality policy and objectives to ensure its effectiveness and suitability.

- Quality First and Service First is our pledge. In order to serve and support our clients better, we would establish a special team called Technology and Cost Team. So Best Practice (top quality and competitive price) will be submitted to you in the shortest time. Green vitality sincerely welcomes you and hopes to be the most suitable and steadiest partner of you.

- We promise, and we do!

Product List:

Sincere Invitation:

Welcome your visit our company.

It's our pleasure if we are able to work together with you to provide the value added service and help to make the optimum mold solution & product.

Any more information about our company and products, pls feel free to visit: http://www.gv-mold.com

Any ideas, contact us today!

Green Vitality Industry Co., Limited was founded in 1993, as starting from CNC processing in a

Small tooling building in Chang'an town, with more than 20 years experience in custom tooling

And injection molding, nowadays we have become one of the global famous mold makers in

Manufacturing large plastic injection molds. With the modern business management system and

ISO9001: 2008 Quality System guideline, the sophisticated production techniques, the advanced

Manufacturing equipment, and our qualified and dedicated team, we are full of capabilities and

Have great confidence in offering you professional one-stop solution of mold designing, mold

Making, injection molding and beyond-value service. We serve a broad range of customers in the

Field of Auto Parts, Aero parts, Household Appliance, Industrial and Beauty. Green Vitality make

Over 400 molds per year, mainly of the molds and plastic parts are exported to America, Germany,

France, Turkey, Italy and other countries worldwide. We have established long-term cooperation

With our clients and are continually improve top quality molds and plastic parts to our clients,

Establishing close strategic partnership to keep customer's satisfaction and success, growing up

Together with customers.

Factory Profile

6000 square meters mold making workshop, 8, 000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

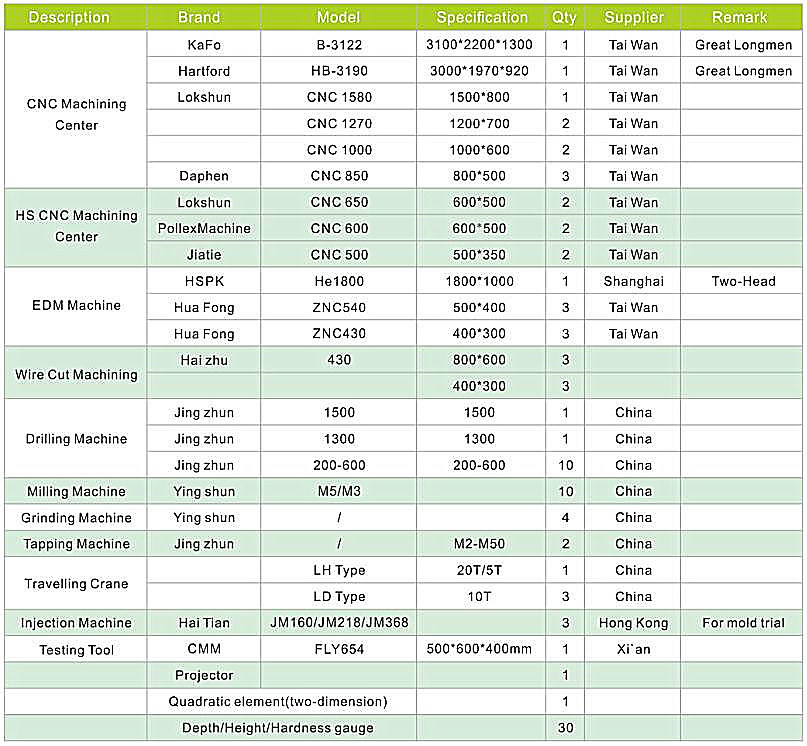

Factory Capability:

40 molds per month (Max. )

Max. Mold size 3200X2200mm, Max. Mold weight 25 tons

Service Scope:

Expert in Auto Parts, Aero parts and Household Appliance large plastic molds

Plastic parts injection

Prototype parts

Market Advantage:

Top quality mold and plastic parts

Reliable service

Small tooling building in Chang'an town, with more than 20 years experience in custom tooling

And injection molding, nowadays we have become one of the global famous mold makers in

Manufacturing large plastic injection molds. With the modern business management system and

ISO9001: 2008 Quality System guideline, the sophisticated production techniques, the advanced

Manufacturing equipment, and our qualified and dedicated team, we are full of capabilities and

Have great confidence in offering you professional one-stop solution of mold designing, mold

Making, injection molding and beyond-value service. We serve a broad range of customers in the

Field of Auto Parts, Aero parts, Household Appliance, Industrial and Beauty. Green Vitality make

Over 400 molds per year, mainly of the molds and plastic parts are exported to America, Germany,

France, Turkey, Italy and other countries worldwide. We have established long-term cooperation

With our clients and are continually improve top quality molds and plastic parts to our clients,

Establishing close strategic partnership to keep customer's satisfaction and success, growing up

Together with customers.

Factory Profile

6000 square meters mold making workshop, 8, 000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

Factory Capability:

40 molds per month (Max. )

Max. Mold size 3200X2200mm, Max. Mold weight 25 tons

Service Scope:

Expert in Auto Parts, Aero parts and Household Appliance large plastic molds

Plastic parts injection

Prototype parts

Market Advantage:

Top quality mold and plastic parts

Reliable service

More >