Home LED Light Products Auto Shuttle Rack for Frozen Warehouse

Auto Shuttle Rack for Frozen Warehouse

| Price: | US $ 18000-23000/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T |

| Prod Model: | WAP 2.0 |

|---|---|

| Speed: | 0.6-0.8m/S |

| Guide Rail Thickness: | 2.5,2.75,3.0mm |

| Battery: | Lithium Battery |

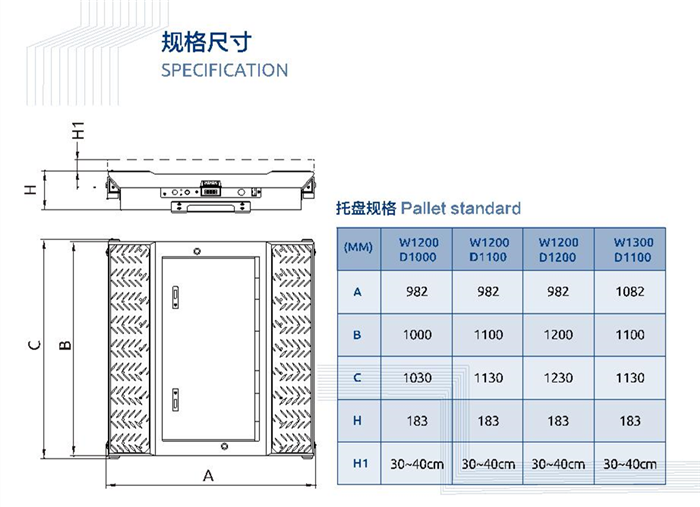

| Height Of Cart: | 183mm |

| Material: | Steel |

| Mobility: | Mobile |

| Closed: | Closed |

| Development: | New Type |

| Serviceability: | for Special Purpose |

| Structure: | Remote Controll |

| Type: | Compact Storage |

| Height: | 180mm |

| Weight: | 500kg-1500kg |

Product Description

Product Specifications:Shuttle racking, is a deep lane storage and retrieval system. The pallet shuttle system consists in a specific rack and a mobile shuttle. This shuttle is a self-powered device that runs on rails in the storage lanes for the loading and unloading of pallets. It is transported to its location at the

front or the back of a lane (in case of open back side) by a standard forklift. Once at its home position, the shuttle performs the loading and unloading tasks without any human intervention.

These tasks are instructed by the fork lift driver using a remote control. Once the tasks are completed the shuttle returns to its home position and is then ready to be transported to a new location for a new task.

By introducing more shuttles into a racking system, the performance will increase. The system can be used for new installations as well as for refurbishments, and is independent from the number and the depth of the lanes. The systems is widely used in food, FMCG, Cold chain logistic area, etc.

2. Clear benefits and advantages:

- A shuttle system offers highest possible density storage and is considered the best solution amongst not fully automated systems

- The system is semi-automated and works in combination with a fork lift truck.

- While the shuttle transports the load within the racking, the fork lift driver is free to work elsewhere, thus he is optimizing his working time.

- Compact storage of another article (SKU) on every lane.

- Ability to handle the pallets FIFO and LIFO. And the possibility to change at every time. Both can be available in the same block. What we call 'Maximum Flexibility'

2. Techincal Specifications:

| Items | DATA | Items | DATA |

| Loading capacity | ≤1500KG | Rated Voltage | 26v |

| Speed without load | 1.1 m/s | Battery Duration | ≥8h |

| Speed with load | 0.8 m/s | Remote range | 100m |

| Acceleration without load | 0.8 m/s2 | Charging time | 3h/85% |

Standard configeration:

| Items | Name | Specification | Quantity | |

| Standard configuration | Shuttle main body | W****D*** | 1 SET | |

| Lithium Battery | 26V/60AH | 1 SET | ||

| Battery Charger | 29.4V | 1 PCS | ||

| Remote controller | T60TX-15DML | 1 PCS | ||

| Lock of battery compartment | C19*20L | 1 SET | ||

| Expanded configuration | WMS, AUTOMATIC INVENTORY,PAD | |||

3. Shuttle operational requirements

Pallet

For a good operation and the shuttle is a moving transport device, a good quality pallet is required. The pallet surface should be closed (no mesh patterns), unless stated otherwise.

- Wooden pallets of good quality, allowing the span between the 2 pallet-rails, with a maximum pallet deflection of 20mm

- The pallet and/or load have a fully closed strip in the middle for the detection of the sensors

- Damaged pallets

- Pallets with too high deflection

- Pallets with an open bottom construction

- Containers and metal support structures

- Operating temperature: from -30°C to +35°C

- Relative humidity: max 80%

- Shuttle better always remains in the cold-store environment

- Before switching on the power again the shuttle must be dry (no condensation)

· Dusty, sandy, humid, combustible,… environments

4. Warehouse conditions/Cold Store

- Keep the shuttle always INSIDE the Cold Store

- But charge the batteries always OUTSIDE the Cold Store

charge only after warming up to normal temperature - So in 3 shift applications best to use 3 battery packs :

1 warming up

1 charging in the battery station.

- Battery and shuttle must be completely dry before connecting

- For existing Cold Store Rooms check for condensation or icing on rails, floors

- For NEW Cold Store Warehouses check if a intermediate area is foreseen between ambient and frozen zone, humidity around a frozen storage zone is prohibited.

5. RFQ Documents:

Before you send us your requirement for quotation, please prepare the following information:

- Warehouse layout CAD drawings if available.

- Pallet size, entry side, width, depth, height of goods.

- Loading weight per pallet.

- Clear height of the warehouse

- Your forklift information, working aisles width and max. reaching height.

- Your intra logistic flow within the warehouse.

Shanghai Calin Logistic Equipment Co. Ltd. Is one of the professional suppliers for storage and logistic equipment with the specialty of racking design, manufacturing, sales and services. The company is located in Changning District, Shanghai. Our main business is to provide racking systems for the storage of palletized or small goods and longer items.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.