Home LED Light Products Automatic Composite Tube Filling and Sealing Machine for Liquid

Automatic Composite Tube Filling and Sealing Machine for Liquid

| Price: | US $ 7500-25000/Set |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T |

| Prod Model: | FGF03 |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Tube Type: | Composite Tube, Aluminum and Plastic |

| Filling Head: | Usually One or Customized |

| Material Of Feeding Hopper: | SUS304/316L or Customized |

| Main Material Of The Machine: | SUS304 |

| Automatic Type: | Fully Auto |

| Function: | Automatic Feeding Tube, Filling and Sealing |

| Date Coding: | Yes |

| Dimension: | Refering |

| Warranty: | One Year |

| If Semi-Auto: | Customized |

| Type: | Volumetric Filling Machine |

| Automatic Grade: | Fully Automatic |

| Material Type: | Liquid |

| Filling Valve Head: | Single-Head |

| Feed Cylinder Structure: | Single-Room Feeding |

| Dosing Device: | Plunger |

| Filling Principle: | Pressure |

| Packaging Container Lifting Structure: | Pneumatic Lifting |

| Structure: | Rotary |

| Packaging Material: | Composite Materials |

| Packaging Type: | Aluminum Plastic Composite Tube |

Product Description

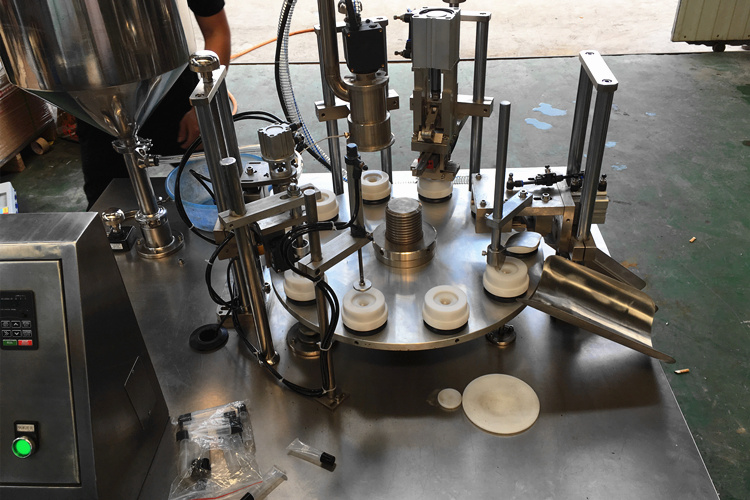

Automatic Composite Tube Filling and Sealing Machine for Liquid

Introduction:

FGF tube filling and sealing machine is usually used for material's package using the composite hose as the packing container,such as aluminum-plastics composite flexible tube.

FGF tube filling and sealing machine is usually used for material's package using the composite hose as the packing container,such as aluminum-plastics composite flexible tube.

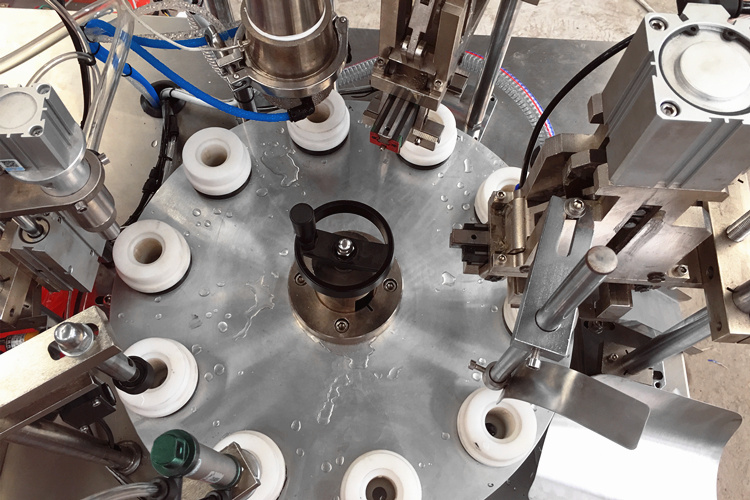

After tube-feeding,8 tube-position rotates continuously for quantity filling, auto-cut-off, heating sealing and tube ejecting.

It is used for the product's packing in the fields of medicine, daily chemical products products, food and fine chemical industry, for example. The filling and tail-sealing for the ointment,hair dyes,pigments,toothpastes,shoe polishes and adhesives.

Features:

★ made of stainless steel

★ made of stainless steel

★ button-controlled and easy to adjust filling quantity and speed

★ No liquid leak and clean

★ pneumatic-controlled

★ For the special industry, It adds the gas protection device to prevent the solidification phenomenon occurring during transportation and storage process after the materials are sealed.

★ The machine is suitable for various size of plastic tube for filling, sealing, and date printing. It is featured with performance. Optional: pot heating system, against-trail-out filling head.

The Filling Process:

tube feeding → tube position (hose container) → automatic identification label located on pipe → filling quantity control test → filling→ heating the tube (inner heating for plastic tube, outer heating for compound tube)→ tail shaping and sealing → tail cutting → Print → finished discharge code.

Technical parameters :

The Filling Process:

tube feeding → tube position (hose container) → automatic identification label located on pipe → filling quantity control test → filling→ heating the tube (inner heating for plastic tube, outer heating for compound tube)→ tail shaping and sealing → tail cutting → Print → finished discharge code.

Technical parameters :

Voltage | 220V 50Hz |

Filling capacity | 20-30 pcs/min |

Filling quantity | 50ml, 100ml, 200ml |

Quantity error | <2% |

Compressed air | pressure 0.6-0.8Mpa |

Air consumption | <30( dm³/min ) |

Dimension | 1230mm*700mm*1400m |

More pictures:

FAQ

Q1.Why choose us?

More than 15 years history of manufacturing machine.

Well experienced professional technical team.

Products as customized.

Price advantage with high quality and excellent service.

Q2.What's your main products?

Vacuum emulsifying machine,homogenizer,cream making machine.

Mixing machine,high speed dispersing machine,double planetary mixer.

Filling machine and sealing machine,tube filling sealing machine,packing and racking machine.

Colloid mill machine,crusher,grinding machine and other mixers.

Mixing tank,storage tank,reaction tank.

Q3.What about components are broken?

The warranty is one year.

If it is in warranty,we will send you a new one for free to replace right after we confirm the reason by EMS,DHL or TNT.

If it is out of warranty,the new components will be charged.

Q4.How to get contacted directly?

WhtasApp, Skype, Viber, Messenger Avaible

SEND INQUIRY FOR MORE CONTACT WAYS.

WILL GIVE YOU ANSWERS WITHIN 18 HOURS.

Wuxi Nuoya Machinery Company Limited, specialized in Industrial equipments & devices ranging from fine chemical industry, petrochemical industry, coating and printing ink, pesticides, daily chemical products and papermaking, and more mechanical solutions for any clients's custom making services, etc.

Our enterprise much focusing on our clients' services and supporting as needed as necessary with our skillful experiences and powerful technical supporting by our indenting and invested Research and Development Staff & Partners seriously for over 16 years long up till now this moment, and further more we are going to budget more for our manuacturing and developing capabilities! ! !

We are running our business always with our own enterprise culture as herein.

Company Spirit: Preciseness, development, innovation

Company Goal: Create the most benefit for the clients

Quality Principle: Keep improving the quality and try to manufacture the first-class products

Service Tenet: Excluding the troubles of the broad users and provide the perfect service.

Our enterprise much focusing on our clients' services and supporting as needed as necessary with our skillful experiences and powerful technical supporting by our indenting and invested Research and Development Staff & Partners seriously for over 16 years long up till now this moment, and further more we are going to budget more for our manuacturing and developing capabilities! ! !

We are running our business always with our own enterprise culture as herein.

Company Spirit: Preciseness, development, innovation

Company Goal: Create the most benefit for the clients

Quality Principle: Keep improving the quality and try to manufacture the first-class products

Service Tenet: Excluding the troubles of the broad users and provide the perfect service.