Home LED Light Products CNC Full-Automatic Glass Cutting Machine Line Xc-CNC-2620

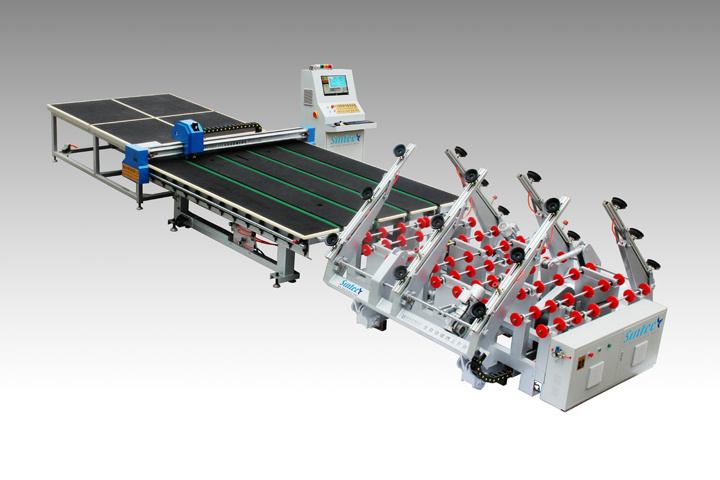

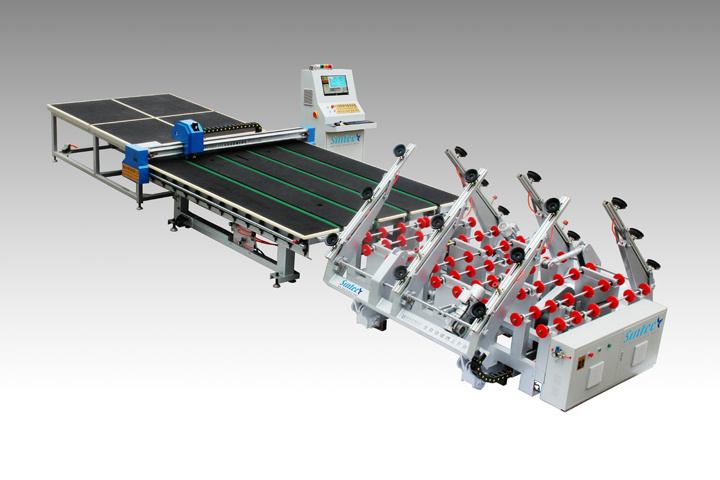

CNC Full-Automatic Glass Cutting Machine Line Xc-CNC-2620

| Price: | US $ 10000-20000/Set |

|---|---|

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T |

| Prod Model: | XC-CNC-2620 |

|---|---|

| Max. Glass Sheet Size: | 2600*2000mm |

| Glass Thickness: | 2-19mm |

| Dimensions (L*W*H): | 11000*3000*1300mm |

| Max. Cutting Speed: | 160m/Min |

| Air Pressure: | 0.6~0.8MPa |

| CNC System: | Galil (USA) |

| Optimization Software: | Optima (Italy) |

| Servo Motor: | Yaskawa (Japan) |

| Pneumatic Parts: | Airtac (Taiwan) |

| Low Voltage Electric Parts: | Schneider (France) |

| Type: | Glass Cutting Machine |

| Certification: | ISO |

| Control System: | Galia USA |

Product Description

XC-CNC-2620 Automatic Glass Cutting Line

The line mainly contains three sections:

1. XC-SP-2620 Automatic Glass Loading Machine

2. XC-CNC-2620 Automatic Shaped Glass Cutting Machine

3. XC-QP-2620 Glass Breaking Table

1. XC-SP-2620 Automatic Glass Loading Machine

Mechanical characteristic:

- Mn bridge steel (Q345A ), perfect surface treatment

- High quality vacuum system, fast sucking speed and high stability

- One key original reset function, for improving work efficiency

- Trouble alarm system and safety alarm system

- Four-bar linkage glass lift structure

- High density PU material glass convey wheel

- Acrylonitrile-butadiene rubber suck disc

- 40CBM/hour vacuum pump

- Enclosed wire and air pipe set

Main parts list:

PLC: Omron (Japan)

Touch screen: MCGS

Converter: Teco (Taiwan)

Sensor: Omron (Japan)

Technical introduction:

- Tilt and suck: tilt angle adjustable, 3-19mm glass sheet auto-suck, suck depth 750mm

- Chain convey after glass suck

- Both auto and manual modes

- Auto alarm system and emergency button for make sure safety operation

- English language touch screen operation

- Glass sheet quantity and station position auto set

- Loading sequence: move-arm tilt up-glass sheet sense-glass sheet vacuum suck-move back-arm tilt flat-glass transmit to cutting table

Technical parameter:

| Model | Max. glass size | Thickness | Dimensions (L*W*H) | Power | Air pressure |

| SP-2620 | 2600*2000mm | 2~19mm | 3560*2200*900mm | 8KW | 0.6~0.8MPa |

| SP -4228 | 4200*2800mm | 3~19mm | 5000*2850*900mm | 8KW | 0.6~0.8MPa |

| SP -5133 | 5100*3300mm | 3~19mm | 5400*3000*900mm | 8KW | 0.6~0.8MPa |

| SP -6133 | 6100*3300mm | 3~19mm | 6430*3340*900mm | 8KW | 0.6~0.8MPa |

2. XC-CNC-2620 Automatic Glass Cutting Machine

Mechanical characteristic:

- Mn bridge steel (Q345A ), perfect surface treatment

- Perfect machine body structure makes sure the tale flat enough and no out of shape

- Japan SMC valve controls the cutting pressure according to different thickness glass

- Cutter head 360 degree rotation, cutter head buffers up and down for glass and cutter protections

- High density water-proof table

- Imported felt, high flatness, antistatic

- 3D edge searing system, high precision automatic location function

- Automatic lubrication system, work in step with cutter head

- Air float function and belt transmit

- Linear guide rail makes sure the high cutting precision and low noise

Main mechanical parts:

Table panel: high density water proof panel (flatness≤±0.20mm/m)

Rack and rail: KHK Japan

Guide rail: Hiwin Taiwan

Belt: Maiku (Joint venture)

Cutter wheel and cutter holder: Bolhe Germany

Main electric parts:

CNC System: Galil (USA)

Optimization software: Optima (Italy)/Guiyou (China best brand)

Servo motor: YASKAWA (Japan)

Pneumatic parts: Airtec (Taiwan)

Low voltage electric parts: Schneider (France)

Cutting pressure valve: SMC (Japan)

Technical parameter:

| Model | Max. glass size | Thickness | Dimensions (L*W*H) | Max. speed | Air pressure |

| CNC-1512 | 1500*1200mm | 2~19mm | 2480*2240*1275mm | 150m/min | 0.6~0.8MPa |

| CNC-2620 | 2600*2000mm | 2~19mm | 3560*2912*1300mm | 150m/min | 0.6~0.8MPa |

| CNC-4228 | 4200*2800mm | 3~19mm | 5320*3100*1300mm | 160m/min | 0.6~0.8MPa |

| CNC-5133 | 5100*3300mm | 3~19mm | 6150*4212*1300mm | 160m/min | 0.6~0.8MPa |

| CNC-6133 | 6100*3300mm | 3~19mm | 7150*4212*1300mm | 160m/min | 0.6~0.8MPa |

3. XC-QP-2620 Glass Breaking Table

Mechanical characteristic:

- Air float function

- Breaking bars 1+2

- High density water-proof table

- Imported felt, high flatness, antistatic

- Breaking bars foot switch control

- Partial design for standard container load

CNC GLASS CUTTING LINE PARAMETER TABLE SHEET:

| Model | Max. glass size | Thickness | Dimensions (L*W*H) | Max. speed | Air pressure |

| CNC-2620 | 2600*2000mm | 2~19mm | 11000*3000*1300mm | 150m/min | 0.6~0.8MPa |

| CNC-4228 | 4200*2800mm | 3~19mm | 14500*3600*1300mm | 160m/min | 0.6~0.8MPa |

| CNC-5133 | 5100*3300mm | 3~19mm | 17000*4212*1300mm | 160m/min | 0.6~0.8MPa |

| CNC-6133 | 6100*3300mm | 3~19mm | 19980*4212*1300mm | 160m/min | 0.6~0.8MPa |

Sintec Glass Machinery Co., Ltd., is located in a beautiful pearl City -- Bengbu, Anhui Province, is a professional high-tech enterprises which produce various kinds of glass cutting machines in China since 2009.

To become a leading international glass cutting manufacturing experts is the Sintec company development strategic target. Quality first and service supreme, made Sintec gained hundreds of domestic and all over the world customers.

After years of efforts, Sintec factory has owned ourselves special design, many patents of products. Company specializing in the production of Automatic Glass Cutting line, CNC Glass Cutting machine, Automatic Glass Loading machine, Glass breaking machine, Semi-automatic Glass Cutting machine, Manual glass cutting machines, Washing machine and various types of glass cutting tools etc.

Cutting production of products applicable to the construction, furniture, windows, hollow, electrical appliance, arts and crafts, all kinds of glass plate in deep processing glass jobs.

Sintec for its excellent quality and perfect after sale service by the customers trust and support,

We will take sincere attitude of friends at home and abroad, joint development of glass machinery manufacturing industry brilliant tomorrow!

To become a leading international glass cutting manufacturing experts is the Sintec company development strategic target. Quality first and service supreme, made Sintec gained hundreds of domestic and all over the world customers.

After years of efforts, Sintec factory has owned ourselves special design, many patents of products. Company specializing in the production of Automatic Glass Cutting line, CNC Glass Cutting machine, Automatic Glass Loading machine, Glass breaking machine, Semi-automatic Glass Cutting machine, Manual glass cutting machines, Washing machine and various types of glass cutting tools etc.

Cutting production of products applicable to the construction, furniture, windows, hollow, electrical appliance, arts and crafts, all kinds of glass plate in deep processing glass jobs.

Sintec for its excellent quality and perfect after sale service by the customers trust and support,

We will take sincere attitude of friends at home and abroad, joint development of glass machinery manufacturing industry brilliant tomorrow!

More >