Home LED Light Products Automatic Bottle Washing Machine Manufacturers

Automatic Bottle Washing Machine Manufacturers

| Price: | US $ 15000-35000/Piece |

|---|---|

| Min Order: | 1/Piece |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: | R-VF |

|---|---|

| Condition: | New |

| Cumputerized: | Cumputerized |

| Certification: | Ce,GMP,ISO |

| Customized: | Customized |

| Power: | 1.8kw |

| Customer Bottles: | 50ml |

| Net Weight: | 500kg |

| Type: | Volumetric Filling Machine |

| Automatic Grade: | Automatic |

| Material Type: | Liquid |

| Filling Valve Head: | Multi-Head |

| Feed Cylinder Structure: | Single-Room Feeding |

| Dosing Device: | Capacity Cup |

| Filling Principle: | Atmospheric Pressure |

| Packaging Container Lifting Structure: | Pneumatic Lifting |

| Structure: | Rotary |

| Packaging Type: | Bottle |

| Packaging Material: | Bottle |

Product Description

1.1 Introduction

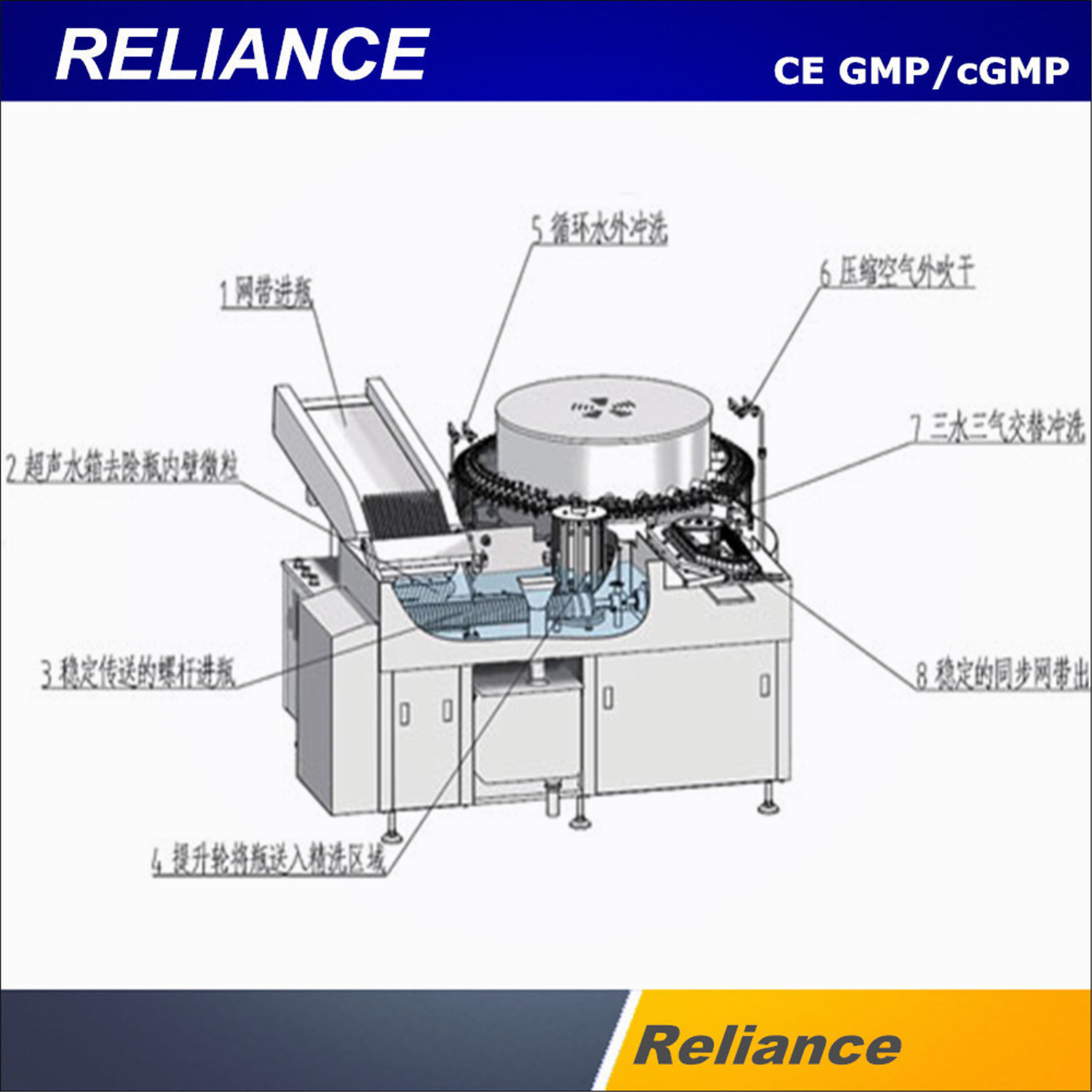

Washing machine including mesh parts for bottle feeding, ultrasonic washing parts, screw auger for bottle holding and lifting, water and gas cleaning parts, bottle come-out, water -gas circulation.

1.2 Working principle

The glass vials will get into the entrance of washing machine, and the auger will lock and turnover the bottle get into the washing station, the water will clean the insert bottle first after then the gas will try and bottle.then get into next station.

1.2.1 Bottle feeding Mesh belt

Mesh belt for bottle feeding including motor, mesh belt, speed adjusting, highest adjusting device.

1.2.2 Ultrasonic washing parts

Ultrasonic washing pars including conveyor, spray groove, ultrasonic box and ultrasonic transducer.

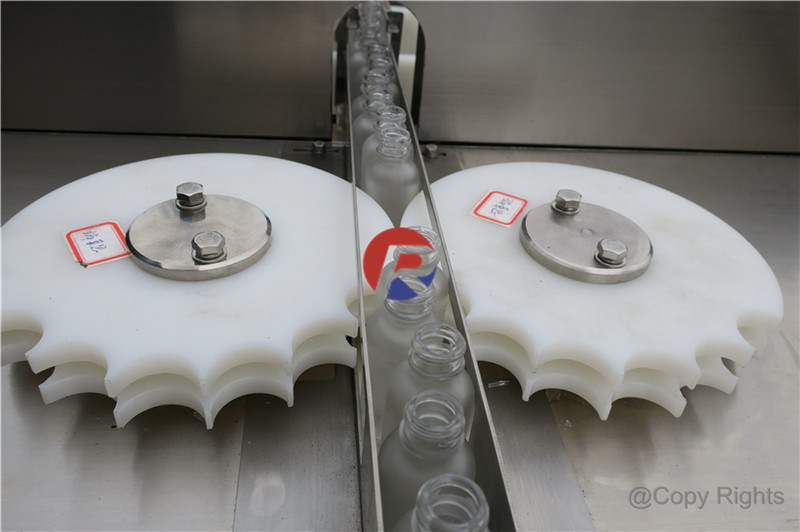

1.2.3 Screw auger for bottle holding and lifting

Screw lifting device including screw auger, lifting cam indexer, lifting wheel.

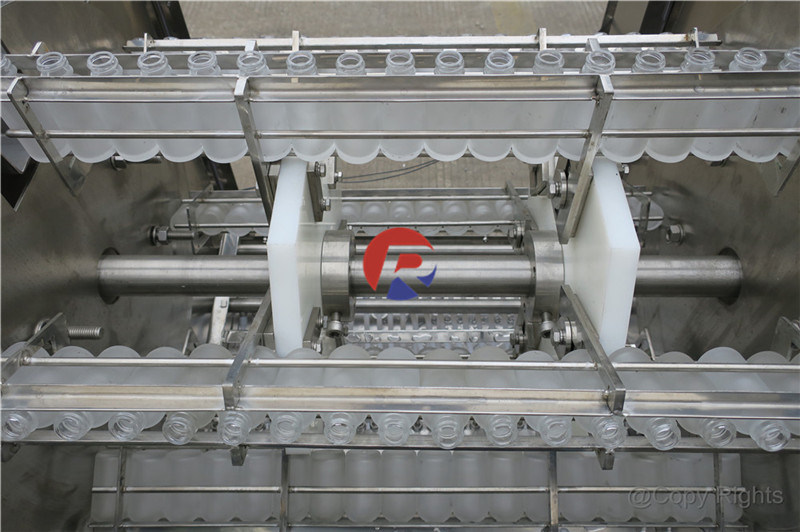

1.2.4 Water and gas cleaning parts

Waster and gas cleaning parts including auger, star wheel, 4 waster cleaning nuzzles and 6 gas drying nuzzles.

1.2.5 Bottle feed-out parts

The feed-out parts of washing machine including star wheel, holder , track plate, long barrier and short barrier track tunnel.

1.3 Relative system

Water and gas circulation system including air compressing system, water injection system, and water circulation system.

1.3.1 Compressed air System

Air compressing system including voltage regulator, pneumatic diaphragm valve, Filter, manual diaphragm valve, pressure transmitter, after cleaning the inside and outside of vials, the system will control each air for valves.

1.3.2 Injecting Water system

Injecting water system including Filter, pneumatic diaphragm valve, diaphragm valve, pressure transmitter to finish cleaning of inside of vials.

1.3.3 Water circulation systemWater circulation system including ring-shape Tank, storage tank, circulating water pump, filter, manual diaphragm valve, Pressure transmitter, spray tank and ultrasonic cleaning tank and so on . The water will feeding for no1 and no2 nuzzles for washing inside of bottle and outside of bottle, when the bottles immerse water, nuzzles will full of bottle for cleaning.

1.3.4 Lay out of washing machine :

1.3.5 Main Technical Parameters

| Customer Bottles | 50ml |

| Productive Capacity | 60-90bottles/min |

| Power Supply | 380V 50HZ |

| Power | 1.8KW |

| Water Consumption | 0.6-1t/h |

| Compressed Air | 15m³/h 0.3-0.4kg/cm³ |

| Net Weight | 500kg |

| Dimension | 1200(L)×1100(W)×1200(H)mm |

1.3.6 Brand List of machine parts:

| Name | Brand |

| Switch button | Schneider |

| Main motor | ABB |

| Relay | Schneider |

| Air Switch | Schneider |

| Frequency changer | Mitsubishi |

| AC contactor | Schneider |

| Touch screen/PLC | Siemens |

We RELIANCE MACHINERY is a professional designer and manufacture who can provide the widest range of liquid filling machine and contract Turkey project for different industry, customized solutions for every stage of your business growth from set-up to industrial production. Our filling & packing solution will be widely used in Pharmaceutical / Medical, Diagnostic / Biotech, Nutraceutical, Cosmetic / Personal Care, e-Cigarette, Household Products, Chemical Specialties, Food / Beverage industrials.

With more than 10 years experience on tech-developing and manufacturing, Our machines are designed towards cGMP compliances and cover a wide range of processes, including unscramblers, bottle washer & cleaners, liquid fillers, (tipping) pluggers, crimpers, & cappers, labels applicator, shrink wrapper and catoner.

From individual machines to complete lines, we can turn your requirement into reality. --we focus on the application, flexibility, changeover, and total cost of ownership.

The quality and our after service is always beyond the contract.

With more than 10 years experience on tech-developing and manufacturing, Our machines are designed towards cGMP compliances and cover a wide range of processes, including unscramblers, bottle washer & cleaners, liquid fillers, (tipping) pluggers, crimpers, & cappers, labels applicator, shrink wrapper and catoner.

From individual machines to complete lines, we can turn your requirement into reality. --we focus on the application, flexibility, changeover, and total cost of ownership.

The quality and our after service is always beyond the contract.