Home LED Light Products Warehouse Drive in Rack

Warehouse Drive in Rack

| Price: | US $ 950-1000/Ton |

|---|---|

| Min Order: | 10/Ton |

| Pay Type: | L/C,T/T |

| Prod Model: | DI90 |

|---|---|

| Floor Rail: | Available |

| Norm: | Fem 10.2.02 |

| Finish: | Galvanized or Painted |

| Proposal Design: | Available |

| Material: | Steel |

| Structure: | Rack |

| Mobility: | Adjustable |

| Height: | 5-15m |

| Closed: | Semi-closed |

| Development: | Conventional |

| Serviceability: | Common Use |

| Weight: | 500kg-2000kg |

Product Description

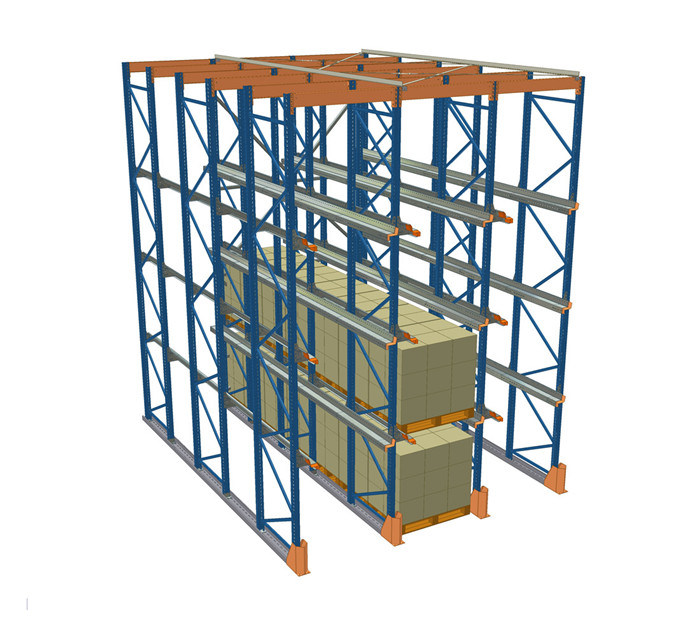

1. Product Description:Drive-In rack consists of a continuous block of racking not divided by aisle, the blocks with no cross beam, the pallet is supported on front to back edge continuous rails cantilevered from the side of upright at each pallet level. Handling truck can drive into block between any upright on the front face to store in and pick up pallets. The system is only access in first in last out situation.

Drive-In rack provide high density storage with limited space, it is mostly used in large quantity with small SKU, store in and out in high frequency. It is found in Cold Store, Beverage Warehouse, Raw Material Store and Milk Packaging warehouse.

2. The basic components

Dive in racking is composed of basic element such as frames, arms and pallet rails. It also consists of a set of horizental bracing and back bracing for system stability. The system is designed for the optimized storage of goods of all sizes and weights.

The finish of all painted parts is an Epoxy-powder coating polymerized at 180 °C.

The standard colors are RAL 5015 (= sky blue) for the frames and RAL 2004 (=pure orange) for the beams. Protectors are painted in RAL 1004 (= golden yellow). Some smaller parts have a galvanized finishing. Special colors are available on request.

There are three types of Drive-in racking based on the loading procedure and accessibility:

1/ Single Access Drive-in

2/ Double Access Drive-in, loaded and unloaded according the LIFO (last in, first out) principle.

3/ Drive-through, loaded and unloaded according the FIFO (first in, first out) principle.

3. Advantages and Key benefits·

Complies with international norms and regulations

· Wide range of basic components for storage of all pallet sizes and weights.

· Many standard accessories to meet every storage need you can imagine

· Computer aided design ensuring the best solution for every application, including static calculations

· Rigid and stable construction

· High quality of finish

· Easy and quick installation

· Mass volume production to offer very cost effective products

4. Factory Production:

5. RFQ documents: Before you send us your Requirement For Quotation, please prepare the following information:

- Warehouse layout CAD drawings if available.

- Pallet size, entry side, width, depth, height of goods.

- Loading weight per pallet.

- Clear height of the warehouse

- Your forklift information, working aisles width and max. reaching height.

- Your intra logistic flow within the warehouse.

Shanghai Calin Logistic Equipment Co. Ltd. Is one of the professional suppliers for storage and logistic equipment with the specialty of racking design, manufacturing, sales and services. The company is located in Changning District, Shanghai. Our main business is to provide racking systems for the storage of palletized or small goods and longer items.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.