Home LED Light Products Warehouse Us Teardrop Pallet Racking

Warehouse Us Teardrop Pallet Racking

| Price: | US $ 975-1050/Ton |

|---|---|

| Min Order: | 17/Ton |

| Pay Type: | L/C,T/T,Paypal |

| Prod Model: | PN90 |

|---|---|

| Upright Hole Type: | Tear Drop |

| Certificate: | ISO9001, Ce |

| Color: | as Requirment |

| Norm: | QS American Standard |

| Material: | Steel |

| Structure: | Rack |

| Mobility: | Adjustable |

| Height: | 5-15m |

| Closed: | Closed |

| Development: | Conventional |

| Serviceability: | Common Use |

| Weight: | 500kg-2000kg |

Product Description

1. Product Description:Teardrop Pallet Storage Racking System,Product Description:

1) Appropriate for picking heavy goods by pallet.

2) High strength and durability.

3) High precision rolling components.

4) Easy for complete installation.

5) Araldite static powder coating.

6) Abundant accessories..

7) Every layer of the board can be adjusted freely;

8) Color and size can be adjusted according to your requirements.

9) The heavy-duty standing posts is good looking and anti-rust with fine powder-coating.

10) Different thickness, size, layers, and colors are available for you to choose

Beam Feature

4 holes 11"*2"*5" P shape beam,slotted connection&bolted connection. Beams can be adjusted every 2".

A, Hot rolled steel moulding, bearing evenly.

B, Various specification and load capacity to meet different storage requirements.

C, Beam hitch steel's teeth are designed to different direction; this not only makes the teeth for increased rigidity.

D, Connection between beams and pillars are performed by safety bolts and clips.

E, Optional accessory is nameplate holder.

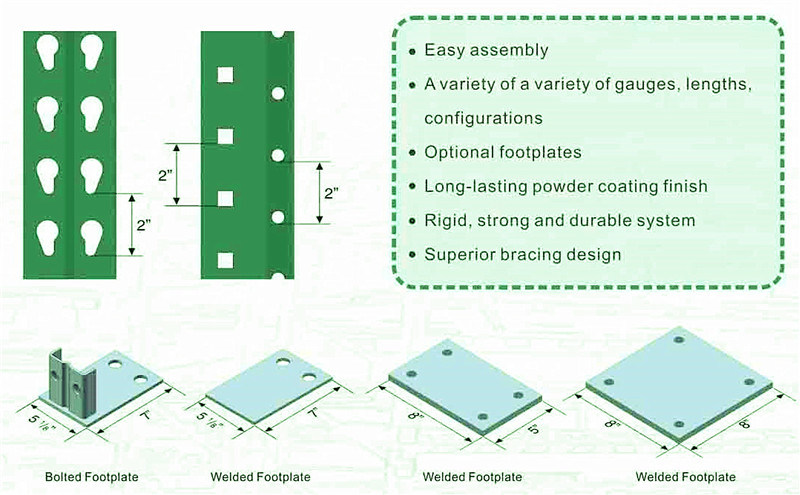

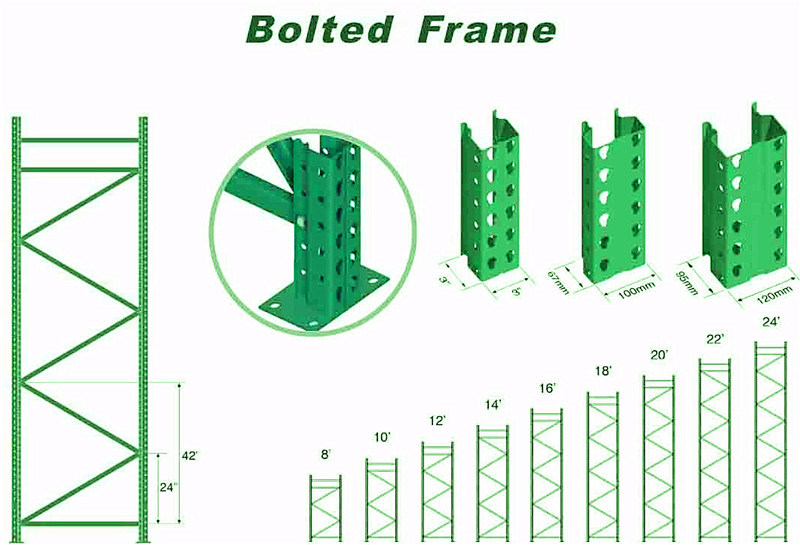

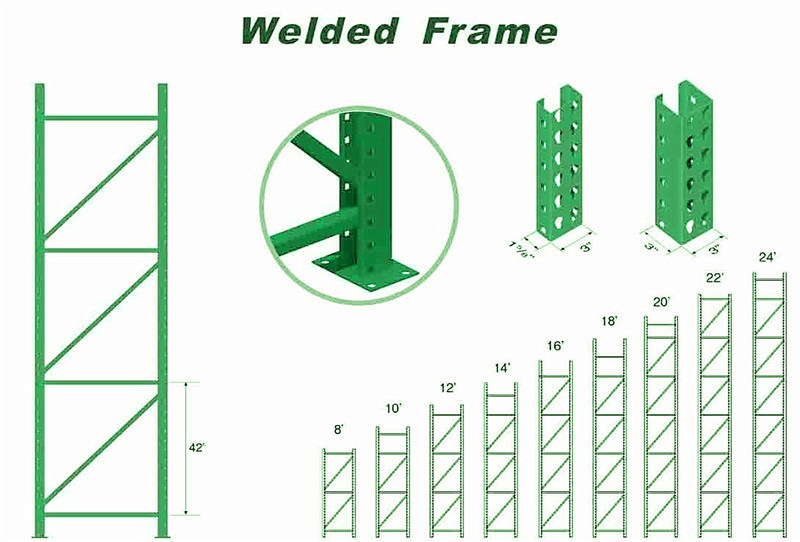

Uprights feature

Both bolted and welded types are available.Beam and column locking system provides exceptional protection against damage, tampering, and accidental disengagement. Durable powder coating and hot-dip galvanized surface treatment, ensure long term using even under the most demanding conditions.

In clined beam has two type longer,one is used loosely for the upper of the rack, the shorter densely for the lower to improve the bearance and solidity.

A, Polyhedron with thirteen faces.

B, Pitch is 50 mm, beam is adjustable.

C, Triangle hole easily tightens to hitch steel and strengthens the load capacity of posts.

Bracings

The horizontal and diagonal bar on standing colunm is square tube,no C-shaped ,square tube is 30*50 ,30*30, and so on.

Support for metal box, Used for placing mesh box and metal container etc. with stacking feet, safe and reliable.

Wood shelf and support bar

The plywood, 20mm thick, is in the salience of knighthead. Each pallet has a pair of knighthead.

Metal shelf

The steel material: cold rolling steel ,SPCC, DC01, ST12,Q195, the steel thickness ranges from 0.6mm to 1.2mm,

Safety locker

Locker, bolted,pin for making racks stability,more strong.

Protector/ barrier

Located at the sides or corners of shelving to be away from impact by forklift.

Pallet stopper

For pallet stop, speciully for fork lift in top oppration.

Row-spacer

Row-spcaer,to be two lines rack connected.

2. Product Specificaitons:

| 1. Dimension & loading capacity | Type: teardrop pallet rack |

| Height: 8', 10', 12', 16', 16', 18', 24' | |

| Depth: 36", 42", 48", 54", 60", 66", 72" | |

| Length: 96", 108", 120", 144" | |

| Special size also available | |

| Loaing capacity per beam layer: 2000-8000lbs | |

| Loading capacity per set: 10000-28000lbs | |

| 2. Main parts specs | Upright: 3"*3" |

| Beam: 3", 3.5", 4", 4.5", 5", 5.5", 6", 6.25", 6.5" | |

| 3. Material | Q235B, Q345B |

| 4. Certification | CE, ISO9001 |

| All manufacturing process is strictly comply with certification requirement | |

| 5. Surface treatment | Finish: powder coating |

| Feature: anti-rust, corrosion protection | |

| Color: as requirement | |

| 6. Advantages | 1) Low capital cost |

| 2) Bottom layer can be stored on the floor to save cost | |

| 3) Easy install and adjust | |

| 4) Compatible with most types of handling equipment | |

| 5) Direct access to all pallets,, pallets can be located and moved freely | |

| 6) Beam height can be adjusted freely per 75mm according to the storage needs | |

| 7. Free sample | Free cut sample is available for quality check |

| Cut sample is ready within 5 days. | |

| 8. MOQ | No MOQ requirement |

| 9. Payment term | T/T, L/C |

| 10. Loading port | Shanghai port |

| 11. Delivery time | 15-25 days based on the quantity |

| 12. OEM/ODM | Available |

| 13. Package | 1) Rack components are bundled with steel belt and covered with plastic film |

| 2) Accessories are packed with carton box | |

| 3) Every package will be marked with label of product name, size and quantity | |

| 4) Air bubble bags are used when loading container to prevent possible goods | |

| move during long distance transportation. | |

| 14. Application | Manufacturing facility, retail center, storage and distribution facility |

4. Advantages and Key benefits·

Complies with international norms and regulations

· Wide range of basic components for storage of all pallet sizes and weights.

· Many standard accessories to meet every storage need you can imagine

· Computer aided design ensuring the best solution for every application, including static calculations

· Rigid and stable construction

· High quality of finish

· Easy and quick installation

· Mass volume production to offer very cost effective products

5. . RFQ Documents:

Before you send us your requirement for quotation, please prepare the following information:

- Warehouse layout CAD drawings if available.

- Pallet size, entry side, width, depth, height of goods.

- Loading weight per pallet.

- Clear height of the warehouse

- Your forklift information, working aisles width and max. Reaching height.

- Your intra logistic flow within the warehouse

Shanghai Calin Logistic Equipment Co. Ltd. Is one of the professional suppliers for storage and logistic equipment with the specialty of racking design, manufacturing, sales and services. The company is located in Changning District, Shanghai. Our main business is to provide racking systems for the storage of palletized or small goods and longer items.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.

The company's Motto is Credibility, Specialty, Innovation and Win-win. Calin provide storage solutions to improve the warehouse usage and logistic efficiency, which creates value for the clients, this is also the mission for the company development.

There are two racking manufacturing plants in Kunshan and Zhenjiang, Jiangsu province, covering the total area of 20, 000 M2 with 150 employees. The factory is equipped with high precision roll forming machine, cold formed and sheet cutting, metal structural components welding and automatic epoxy painting line. The factory has been awarded ISO9001 since 2007. The experienced sales engineers and designers are able to provide "tailor-made" proposals for the clients, so as to provide rapid and most suitable storage solutions.

Our main products are conventional pallet racking, compact storage systems (Mobile pallet rack and Pallet shuttle system), Long span shelving systems and ASRS racking systems total integration. The products are widely used in food industry, auto parts storage, e-commerce logistics, manufacture industry, pharmaceutical, commercial distribution, etc. Our clients include FAW, BMW, Amazon, Siemens, Philips, Emerson, and also include many local developing private companies, as well as the products exported to South East Asia, Middle East, Australia and Europe, etc.